Introduction

When a person orders something online, a lot starts moving behind the scenes. Sorting is one of the most important components of this approach. It is how items move from warehouse shelves onto the best delivery trucks. This stage must be rapid and errorless. Enter the robotic sortation systems. And these machines are sorting packages day and night, with speed and with care. Without them, online shopping would be much slower and clumsier.

Why Humans Alone Can’t Keep Up With Warehousing

Big warehouses process thousands of orders a day. Hand sorting each piece takes time and can introduce errors. People grow weary, distracted, or flummoxed by packages of sameness. Robotic Automation doesn’t face that issue. They scan and they move, they sort nonstop. They don’t take vacations, and they never grow bored. This is essential for keeping warehouses in pace with demand, particularly during peak periods, such as holidays or sales.

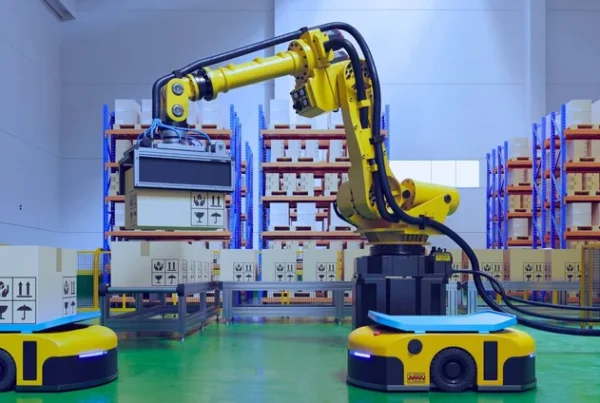

Robotic Sortation Explained

These systems are composed of cameras, scanners, and smart software. A package travels down a conveyor. It is scanned and matched with its drop-off. Then a robotic arm or diverter nudges it onto the right path. It seems easy, and it takes place within seconds. Some can process thousands of packages an hour. That kind of agility is simply not achievable with manual labor.

Speed is Not the Only Goal

It is just not about speed — it is about doing it right. A misdelivered package can lead to delays, refunds, or lost customers. Robotic sorters can prevent this. Their barcode scanners are perfectly accurate. The system examines data live and pre-empts errors before they become an issue. In brief, it is a way for businesses to help keep their promises to customers.

Saving Space, Time, and Money

These systems do more than simply speed things up. They also use space better. Robotic sorters can be constructed in vertical or compact installations. That’s more work in less space. Sorting requires fewer workers, so the costs of labor go down as well. And fewer mistakes mean less lost money on returns or complaints. The system pays for itself in the long run.

Smarter Every Day

Today’s robotic sorters are constantly getting smarter. They are linked to data systems that monitor performance. If a component is slowing down or flawed, it can alert a person. Some alter their paths or speed based on how congested the warehouse is. It’s not just a tool — it’s a smart partner in the act. This sort of tech is revolutionizing how companies think about logistics.

No longer a need for massive systems.

In the past, robotic sorters have been too expensive for all but the largest robotics companies in Dubai. But now they are being adopted by smaller warehouses as well. There are small systems that work on tighter budgets and space. The demand for quick and precise sorting increases as more businesses move online. Robotic systems are going to be must-haves, not luxuries.

The Real Impact You Don’t See

As a customer, you might never see a robotic sorter in action. But you’re benefiting from it every time your order arrives on schedule. The speed, precision, and fluidity that you’ve come to expect from broadcasts likely owe a lot to these machines. They’re the quiet labor behind the fast shipping. And, as online shopping continues to expand, so too will the use of robotic sorters.

Designed to Work Horses Hard and Long

The robotic sortation systems are built to last day in, day out. And they slave away all day, never stopping. No lunch break, no tired arms. This is helpful in 24/7 operations like warehouses.” They are machines that can process thousands of packages without skipping a beat. They are heavy-duty and can accommodate all shapes and sizes. Whether it’s little boxes or giant packages, the system has just kept going. And that means fewer delays and smoother operations.

Helps During Peak Seasons

Order numbers rise during peak times like the holidays. Human teams can’t always keep pace. Mistakes mount, and shipping falls behind. Robotic sorters are doing their part to take the pressure off. They are easily coping with the increase. No hiring and training of temporary workers. That leaves the team to focus on packing and quality checks, as machines do most of the heavy lifting. It keeps the lights on when the orders are coming in hot.

Easy to Track and Monitor

Among the best things about robot systems is that they are so, so easy to follow. All of these millions of items are scanned, cataloged, and tracked in real time. If there is a delay or a problem, you can find out where it occurred. Managers receive updates on performance and system health. You don’t have to guess. It gives you more control and fewer surprises. This is a game changer when you have to process large quantities daily.

Reduces Strain on Workers

What you have NOT written, sorting work can be physically arduous. It requires standing for hours and picking up heavy boxes. This can gradually cause an injury or burnout. Since robots do much of the sorting, human workers feel less pressure. They can do other tasks that demand some level of focus, care, or problem-solving. It helps me to have more balance in my working day. People feel safer and less frazzled at the end of the day.

A System That Grows With You

Your sorting requirements also evolve, as does your business. Robotic sorters can be expanded as necessary. You could integrate more stations or connect more lines. A few are modular, so you don’t have to replace everything. Just do more of the parts you already like. It’s a smart arrangement for businesses that plan to expand. The system is not something you grow out of — it grows with you.

Less Room for Error

Small errors can cause big delays in a busy warehouse. The wrong item cost money and time, and so did missing a delivery slot. This is a risk that can be reduced with robotic sorters. They are careful with every item they scan. They don’t lose focus or confuse orders. This results in fewer mis shipments and less rework. Customers receive the correct items on time, and that builds trust.

Fits Various Products

Not all products are created equal. Some are slim, some are hefty. Some are delicate and require a gentle touch. Robotic automation systems are designed to accommodate this range. They can categorize objects by size, weight, or shape. In a case, they can even handle soft bags or oddly shaped parcels. This flexibility is particularly useful in warehouses with a diverse stock mix. The system caters to the job, not the other way round.

Works Well With Other Tech

Sortation robots, of course, don’t act alone. They connect with scanners, packing machines, and warehouse software. This keeps the whole system running smoothly. When one piece changes, the other can adjust. For instance, if the inventory system receives a new order, the sorter knows where that new product in the order is supposed to go. When you’re building, this link can be a huge time saver and helps prevent mix-ups. All of it moves as a system, not individually.

Improves Warehouse Flow

A warehouse robotics operates most efficiently when everything flows in a sequence. Robotic sorters assist in forming an even flow. Packages don’t accumulate or bottleneck. Workers can tell what’s where and what needs to be done next. It establishes a rhythm that is easy to get behind. This smooth-going stream allows you to temper waste and anxiety. It’s an overall more organized and manageable space.

Becomes Smarter Over Time

Today’s computer systems are not simply following orders; they are also learning from data patterns. The more they do their job, the better they become at doing their job. They see delays or slowness and help fix them. Some are even able to anticipate problems before they rise to the surface. It’s like having an extra pair of eyes on the job — always watching, always improving.

Final Thoughts

Robotic sortation is about more than just a tech upgrade; it’s a crucial part of modern order fulfillment. It keeps the system going, helps businesses expand, and boosts consumer pleasure. From the second that your order is packed to the moment it’s sorted for delivery, these machines are diligently doing their job. Behind each smooth delivery is a system that knows precisely where your package needs to go, and it’s most likely not human.

Stay Connected

Want to see more insights on warehouse automation and smart logistics? Join the conversation and stay updated with the latest in robotic sortation systems by following us on Facebook. We regularly share innovations, case studies, and behind-the-scenes looks into how automation is reshaping fulfillment. Follow us on Facebook and be part of the future of warehousing.