Introduction

The digital transformation in warehousing has reshaped how companies manage storage, fulfillment, and logistics. It is not only about installing robots; it’s about creating intelligent systems that connect automation, software, and people. Modern warehouses require solutions that move goods faster, more accurately, and scale with demand. Automation enables higher productivity, smoother workflows, and improved customer satisfaction.

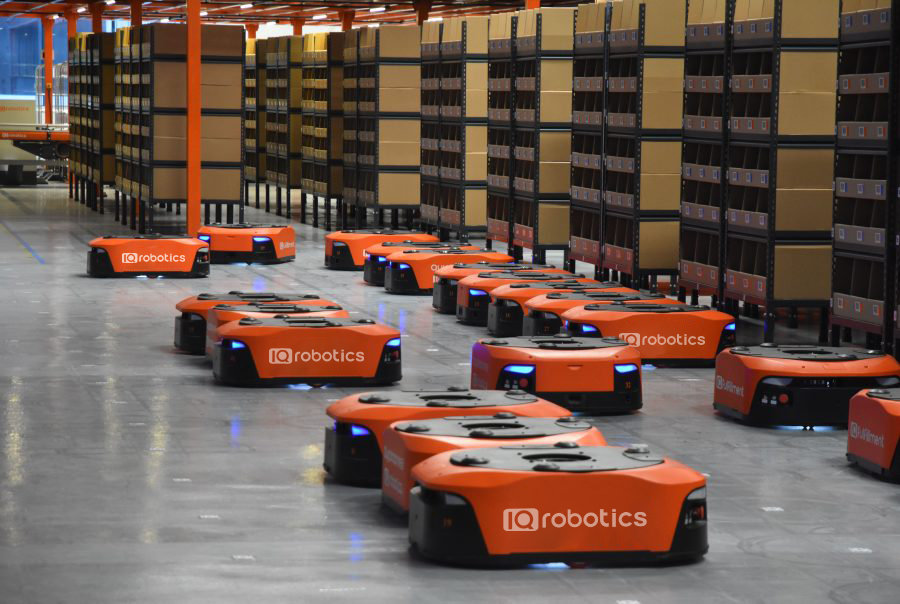

The key player in this shift is IQ Robotics, a leading warehouse automation provider in the UAE. They deliver robotic sorters, conveyors, integrated platforms, and real-time management systems that meet modern supply chain challenges.

The Role of Robotics in Digital Transformation

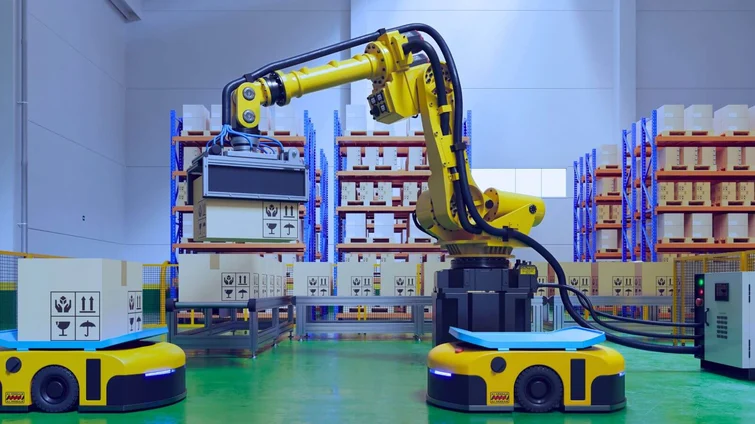

At the core of warehouse modernization is robotics. Robots don’t just move goods—they create efficient, safe, and scalable environments where people and machines collaborate.

They minimize errors, accelerate processes, and adapt flexibly to inventory changes. Robotics also enables predictive maintenance, tracking system health in real time to prevent downtime. This makes robots not just tools, but growth partners in modern supply chains.

Smart Integration of Robotic Systems

One of the most powerful aspects of robotics is step-by-step integration. Companies can implement robotics gradually, without halting daily operations.

AI and machine learning give robots self-learning capabilities. They analyze performance data, detect inefficiencies, and optimize processes—reducing errors and continuously improving warehouse efficiency

Automation Systems as the Backbone

While robots bring intelligence, automation systems form the foundation of warehouse performance. Conveyors, sorters, lifts, and labelers keep goods flowing smoothly inbound and outbound.

Examples include:

- Conveyors: Move goods quickly between zones with minimal manual handling.

- Sortation systems: Ensure items are always in the right place at the right time.

Together, these systems deliver reliability, scalability, and consistent throughput.

Advanced Components Driving Automation

Warehouse automation relies on advanced components that improve accuracy and space utilization:

- Vertical lifts: Maximize vertical storage and speed.

- Industrial labelers: Apply high-speed labels with precision.

- Dimensional weight systems: Accurately measure packages to reduce shipping costs.

These solutions are customizable by space, budget, and throughput. Flexibility is critical in GCC supply chains, where demand surges during Ramadan, sales seasons, or cross-border trade.

Software: The Brain Behind Automation

Automation and robotics depend on software intelligence. The IQ Platform integrates WMS, order management, and transport management into one ecosystem.

This allows managers to:

- Track KPIs in real time

- Monitor shipments and workflows

- Make fast, data-driven decisions

Software ensures that every robot, conveyor, and sorter works toward business goals.

Data and Integration Capabilities

ERP and inventory management systems integrate directly with warehouse automation software, ensuring seamless data flow.

Dashboards and predictive analytics provide real-time insights into KPIs, costs, and performance bottlenecks. This transparency helps leaders respond quickly to customer demand shifts and optimize resources with confidence.

Hardware and Support: The Foundation

The digital warehouse also relies on hardware: picking robots, sorters, conveyors, stackers, and storage bins. Without this physical layer, smart software cannot function.

Support is equally important—covering installation, training, and after-sales service. Together, hardware + support ensure long-term reliability and operational growth.

Training & After-Sales Support

Employees need training to operate and maintain automation confidently. This improves safety, reduces downtime, and increases productivity.

After-sales services ensure high uptime through 24/7 troubleshooting, updates, and manuals. Training + support provide the human connection that makes digital transformation sustainable.

Conclusion

Digital transformation in warehousing goes far beyond robots. It requires an ecosystem of robotics, automation, software, and hardware working together.

IQ Robotics delivers end-to-end automation solutions in the UAE and GCC, helping businesses build flexible, efficient, and future-ready warehouses. Companies that act now will be at the forefront of tomorrow’s logistics.

Contact IQ Robotics for a tailored consultation or follow us on LinkedIn for the latest automation insights.

FAQs

1. What is digital transformation in warehousing?

It goes beyond automation to include robotics, software, and analytics. Together, these create intelligent, flexible warehouses that adapt to demand.

2. What are the benefits of warehouse automation?

Faster operations, fewer errors, reduced labor costs, and scalability during high-demand periods like Ramadan or Black Friday.

3. What role does software play in warehouse automation?

Software is the brain of automation, it coordinates robots, conveyors, and systems while offering analytics and real-time decision-making.