Why Labor Shortages Are Reshaping UAE Warehousing

The labor shortage is one of the biggest challenges facing warehouses in the UAE. With growing demand for faster fulfillment, companies struggle to find enough staff for manual picking, sorting, and shipping. This impacts efficiency, increases costs, and limits scalability.

The solution lies in digital systems and warehouse robots, machines that work consistently, quickly, and with near-zero errors.

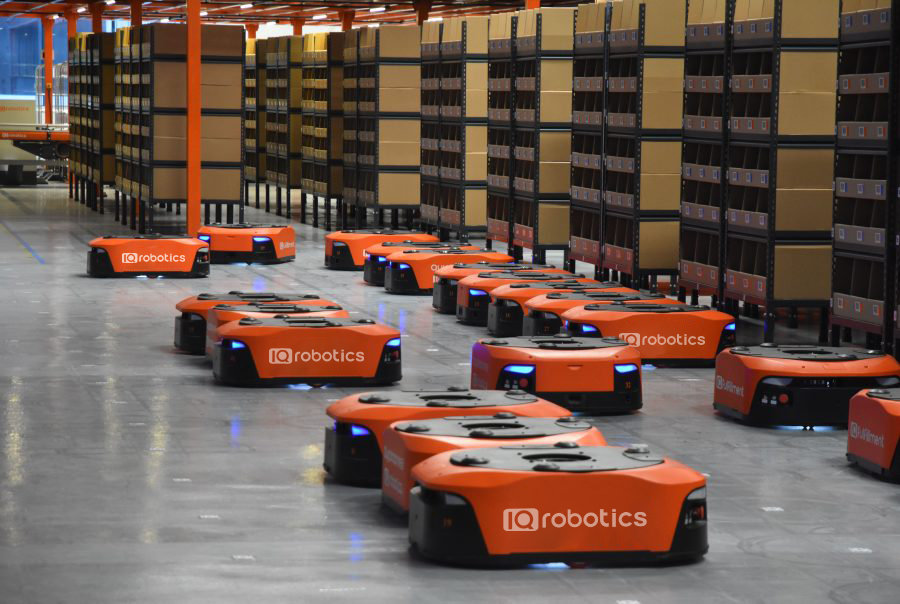

IQ Robotics offers robotics-driven warehouse automation and software solutions that reduce dependence on large workforces. Their services such as robotic sortation and automated picking systems help businesses scale without being constrained by labor shortages.

Robotics Automation as a Strategic Response

Automation is no longer optional; it’s a necessity for UAE companies facing labor shortages. Robots work 24/7 with consistency and accuracy, eliminating issues of fatigue and high turnover.

By automating picking, sorting, and transporting, businesses reduce reliance on manual labor and increase throughput. Robots also improve workplace safety by taking on repetitive, physically demanding tasks, while humans focus on supervision and higher-value roles.

This balance ensures sustainable growth in a region where logistics and e-commerce are expanding rapidly.

Smart Robotic Systems for Workforce Challenges

The strength of robotics lies in flexibility. Modern systems integrate with existing infrastructure, allowing gradual adoption without disrupting operations.

AI and machine learning make robots smarter over time. They optimize workflows, identify inefficiencies, and support predictive maintenance, helping warehouses overcome immediate labor shortages while building long-term resilience.

Automated Systems Driving Productivity Gains

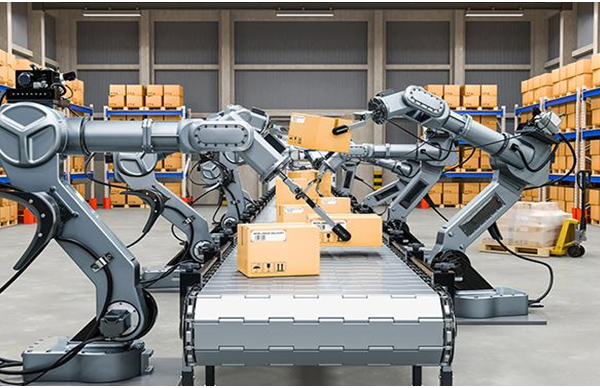

Picking is one of the most labor-intensive and error-prone tasks in a warehouse. Automated picking systems overcome these challenges by enabling robots to identify, grab, and transport items with speed and accuracy.

Key benefits include:

• Consistent, predictable output

• Faster fulfillment for retail and e-commerce

• Reduced seasonal hiring and training needs

• Higher customer satisfaction through on-time, error-free delivery

Key Components of Automated Picking Systems

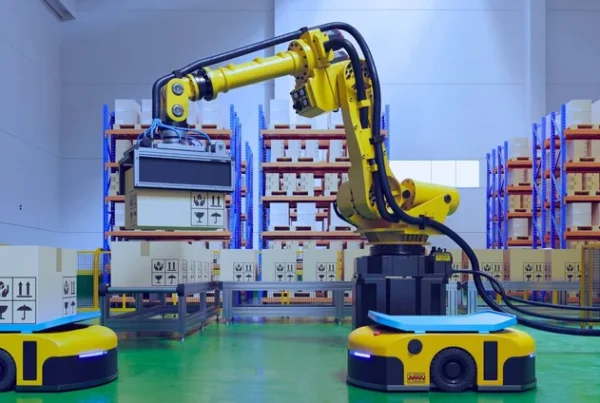

Automated warehouse robots picking combines advanced robotics with supportive infrastructure:

• Robotic arms & conveyors for fast, precise movement

• Sortation systems to direct goods accurately

• Vertical lifts to optimize space across warehouse levels

• Industrial labelers for accurate packaging and tracking

• Dimensional weight systems to cut shipping costs

These solutions are scalable, and businesses can expand automation as they grow. Training ensures human staff can operate and maintain the systems, making the transition from manual to automated smooth and efficient.

Software: The Core of Automation

Robotics warehousing automation depends on smart software. It acts as the brain, coordinating machines, conveyors, and pickers while offering real-time performance insights.

The IQ Platform integrates warehouse management, order management, transportation, and business systems into a unified environment. This enables managers to make data-driven decisions, optimize resources, and stay ahead of labor challenges.

Integration and Real-Time Decision Making

Automation software integrates seamlessly with ERPs and inventory systems, creating smooth data flows across the supply chain.

Advantages include:

• Dashboards showing live order flow, picking rates, and productivity

• Predictive analytics to prevent issues before they arise

• Optimization tools for efficient resource allocation

This transforms warehouses into smarter, more flexible ecosystems.

Hardware and Human Support

Strong robotics systems depend on both hardware and people. Physical infrastructure such as robots, conveyors, sorters, stackers, and trolleys provides the backbone of automation.

Equally important is human support:

• Training ensures staff operate and maintain systems confidently

• After-sales service offers 24/7 troubleshooting, updates, and documentation

Together, hardware and support ensure automation continues delivering results long after installation.

Building Long-Term Sustainability

Warehouse robots are not just a stopgap; they create sustainable growth. Training programs reskill employees for supervisory and technical roles, reducing dependency on low-skill labor.

After-sales support ensures high uptime and efficiency, keeping automation systems optimized. This makes robotics not just a short-term solution, but a long-term driver of supply chain resilience in the UAE.

Conclusion

The UAE’s labor shortages present a challenge, but also an opportunity to transform. Robotics-driven automation delivers accuracy, productivity, and safety while reducing reliance on large workforces.

Automated warehouse robots picking systems, in particular, solve one of the most labor-intensive tasks and allow businesses to respond to growing demand.

IQ Robotics provides end-to-end solutions: robotics, automation, software, hardware, and support—to help warehouses future-proof their operations. Companies that adopt now gain a decisive edge in efficiency and growth.

Contact IQ Robotics for a tailored consultation or follow us on LinkedIn for the latest automation insights.

FAQs

1. How do warehouse robots reduce labor dependency?

By automating repetitive tasks like picking and sorting, robots reduce reliance on large workforces and increase speed and accuracy.

2. What are the benefits of automated warehouse picking systems?

They improve accuracy, speed, and efficiency while lowering costs and reducing the need for seasonal hiring.

3. Can robotics be integrated into existing warehouses?

Yes, robotic systems are designed to integrate gradually, allowing businesses to adopt automation without disrupting daily operations.

4. Why is software critical in warehouse automation?

Software coordinates all robotic systems, provides real-time visibility, and connects with enterprise tools to optimize performance.