Warehousing faces constant pressure to deliver faster, more accurate results. Rising demand and manual processes cause errors, making Management Software and digital transformation essential for survival. Warehouse Automation Software enables warehouses to coordinate and execute daily work in a logical, intelligent order. It adds centralised management for siloed practices and provides increased transparency across the enterprise. Automation provides businesses with significantly improved speed, consistency, and certainty of operation.

What Exactly is Robotic Warehouse Management Software?

Robotic warehouse management software is a software that controls all warehousing operations on one digital platform. It manages in-process, order movement, and tasking in real-time. The method is limited to connecting workers, machines, and data without any sort of input. Managers have real-time visibility into warehouse activity with live dashboards. Transparent tasking rules enable teams to be clearer-headed and avoid delays. With this powerful tool, you are able to eliminate guesswork for your daily operations and establish predictable processes.

Basic capabilities that maintain daily operations.

There are a few important features that support the efficiency of warehouse automation software. Inventory management in real-time updates stock immediately and avoids miscounts. They also implement tools for managing orders and controlling picking, packing, and shipping. Work assignment distributes work based on priority and the ability to perform it. Motion tracking devices facilitate the accurate manipulation of objects during their motion. Alerts let teams know when there are shortages or delays before they become more serious. The reporting tools tell people what to do better next time.

The Role of Automation in Warehouse Efficiency

Automation ensures better productivity in all warehouse zones. Employees are able to spend less time looking for products and more time doing the jobs they were hired to do. Selection routes get shorter and more organised, reducing fatigue. Order precision increases with guided instructions and instant status updates. Manually-keyed errors are greatly reduced. Operates consistently during the busiest times of year. Automation provides a way to grow warehouses without disrupting operations or adding complexity.

Automation Systems & Infrastructure Support

The warehouse is rounded out with automation software that runs alongside physical infrastructure. Much of this work is being done with the support of warehouse automation systems that provide structure to the process, then automate it away! Such systems may involve conveyors, scanners, and sorting machinery. It also manages the movement between all components of the hardware and helps to prevent congestion. Load balances workloads between zones. Downtime is minimised through improved scheduling and work visibility. An automation controller; the software is the brain behind any classroom, making all mods/sends and mic settings.

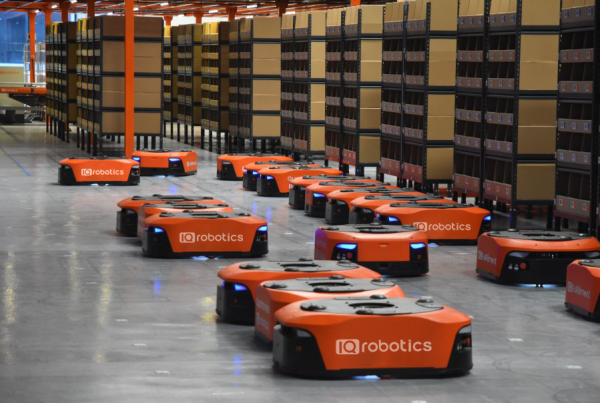

Robotics and Intelligent Warehouse Operations

Warehouses are the home of robots in modern times. Robotic warehouse software manages the robotic tasks with high accuracy. Robots perform repetitive and backbreaking labour with ease. The software keeps robots in sync with other human workers. Each task is rebalanced, and the number of tasks per user changes automatically. Robotic movements are uniform and precise. This partnership will optimise throughput, all while ensuring safety and reliability.

ROI Money and the Return on Investment

Automation software provides definite financial returns over time. These labour costs have reduced due to the efficient way in which tasks have been executed. Precision in ordering decreases returns and rework costs. Stockouts are avoided by inventory management. The quicker the fulfilment, the happier the customer, and ultimately, the retention. Movement efficiency makes energy use more efficient. Maintenance planning reduces unexpected downtime. Gradually, these savings accumulate and offer quite a good ROI.

Selecting The Best Automation Software

The choice of an appropriate automation tool is a decision that should be made after thoughtful consideration. Warehouses will have to consider current and future demand when making their decision. Robustness is the ability of a system to grow without the need for it to change. Integration features lower the risks of implementation and downtime. Ease of use makes it easy for teams to apply online. Staff training demands should stay reasonable. A stable technical finish is the guarantee of stability. Rugged security guards are sensitive to operational data.

Conclusion

Warehouse Automation Software provides a proven way to sustainable and efficient warehouse operation. Logistics operations are changing all over the world, as warehouse automation constantly redefines them. Intelligent software Speeds up work, while Accuracy and visibility get boosted. Companies get better control of their daily operations and overall planning. It’s a concept where the cost goes down, and the quality of service becomes better by millions all the time.

Looking to maximise warehouse productivity and profitability?

Sign up at IQ Robotics to get a customized consultation or visit us on LinkedIn to get to know more.

Frequently Asked Questions

What does the warehouse automation software solve?

It lowers errors, increases speed, and provides more operational visibility.

Is warehouse automation feasible for scaling warehouses?

Yes, it enables a high-growth model that scales without derailing operations.

How long does it take to implement warehouse automation?

Installation time varies according to the size of the warehouse and the complexity of operations.

Does warehouse automation software take jobs away from workers?

It already has aid built in for workers who don’t need to push as much paper.

Is it compatible with your current systems’ automation software?

The majority also connect seamlessly to inventory and order platforms.