Introduction

In the increasingly complex landscape of logistics and supply chain management, AI is no longer just a concept ahead of its time; it is a reality today that is transforming the very nature of how goods are transported and moved, how warehouses operate, and how businesses respond to demand. With the rise of AI-powered warehousing, volumes of global trade are being managed more efficiently, and consumers’ demands for shorter delivery times are being met with greater precision. AI technology has become one of the most critical enablers of innovative, efficient warehousing systems. From optimizing inventory to predictive analytics, AI is redefining the building blocks of supply chains at every level.

The Rise of Smart Warehousing

Historically, the warehouse was an analogue environment, reliant upon a human workforce and fixed workflows. The first wave of automation emerged with the digital revolution, barcode scanners, conveyor belts, and warehouse management systems (WMS) streamlined operations and reduced errors. However, the warehouses of today are advancing beyond automation and moving forward to intelligence. Machine learning, data analytics, computer vision, and robotics are gradually being integrated into warehousing operations. This enables warehouses to operate with reduced human involvement, respond to real-time data, and make more complex decisions instantly.

Machine Learning for Inventory Management

Intelligent inventory management is one area in which AI-powered warehousing can have a significant impact. Conventional inventory management approaches rely on static data and physical counting, which often lead to inaccuracies and stock-outs. That’s where AI comes in, analyzing real-time data from sales, supplier networks, and demand forecasts to make accurate inventory decisions. Machine learning models can also forecast future demand based on historical patterns, seasonality, and external factors such as market trends or weather.

Supporting AI Replenishment

AI is also supporting automated replenishment. The system can initiate a reorder when the stock level reaches a certain threshold. When paired with supplier data and lead times, this ensures continuous supply without delays or human intervention.

Packing and Picking using Robotics and AI

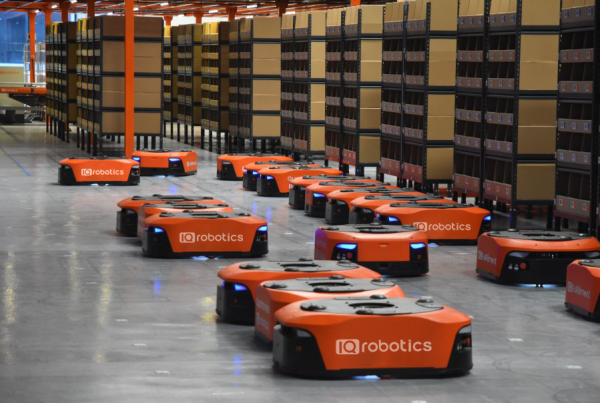

Order picking is among the most labour-intensive operations in large warehouses. It requires workers to walk long distances, locate items, and pack with precision. Artificial intelligence in robotics revolutionizes this process with automated guided vehicles (AGVs), robotic arms, and sophisticated conveyor systems.

- AI-driven computers: Using AI and computer vision, robots navigate complex warehouse layouts, recognize items , and carry out picking tasks autonomously, quickly, and accurately. Collaborative robots, also known as “cobots,” are designed to work alongside human workers, enhancing productivity rather than displacing jobs. AI also improves the efficiency of picking routes, minimizing travel time within the warehouse, and speeding up delivery.

- Improvement in efficiency: Additionally, AI enhances packing efficiency. AI systems can determine the most space-efficient way to pack by analyzing product dimensions, order combinations, and packaging materials. This helps reduce shipping costs and minimize packaging waste — an important consideration for companies focused on sustainability.

Real-Time Monitoring Utilising Computer Vision

- Computer Vision: The part of AI that enables machines to understand visual data is known as computer vision. In warehousing, this is used to monitor real-time operations, track item movement, and enhance safety and security. On the worker safety front, computer vision systems can alert workers to hazards, track adherence to safety protocols, and even predict accidents by identifying abnormal behavior.

- AI-powered cameras can verify that packages are labelled accurately, confirm that items are placed in the correct location, and flag damaged items before they are shipped. They are also pivotal to security, as they can detect trespassers or capture thieves.

Integrating Predictive Analytics in Decision Making

Data is the foundation of any supply chain, but raw data isn’t enough. Understandably, AI takes this a step further by leveraging predictive analytics to transform data into actionable insights. This enables warehouses to anticipate future issues and take proactive measures before problems arise. AI also allows dynamic decision-making. If a disruption does occur, be it delayed shipments or a sudden surge in demand, the system quickly assesses the situation and advises on the necessary action. This real-time flexibility is critical because contemporary supply chains must react promptly to changes.

Use of Supply Chain Network Integration

Warehouses are not isolated; they are part of a larger supply chain network. This integration is reinforced by AI, which enables seamless data sharing and collaboration among suppliers, manufacturers, and distributors in real-time. AI also promotes transparency with end-to-end visibility across the entire supply chain. Additionally, stakeholders can track orders, monitor inventory levels, and respond promptly to disruptions. Such coordination is crucial in global supply chains , which often involve complex logistics and volatile market conditions.

Green Culture with Intelligent Warehousing

Several common principles can help create this collaboration, including, but not limited to, sustainability. Several contributing factors make robotics warehousing automation greener in the supply chain. AI thus minimizes waste and storage needs by optimizing stock levels and reducing excess inventory. Packing smarter uses less material and reduces your carbon footprint during delivery. Improving energy efficiency is another gain. Artificial intelligence can control lighting, heating, and equipment usage according to activity levels in different areas of the warehouse.

Challenges and Considerations

Although the advantages of AI-driven warehousing are apparent, there are also challenges to its implementation. Progress can be slow, owing to high upfront investment, integration with legacy systems, and issues with data quality. IPC also has to help companies address data privacy issues and cybersecurity risks as AI technologies are deployed. You’ll need a cultural change to succeed with the adoption. It is also crucial to select the right AI solutions that are specifically designed for business needs. Traditional tools may not be suitable for specific operational complexities; partnering with technology specialists will lead you to customized systems and scalable results.

Exciting Pathways For AI In Warehousing

The role of AI in warehousing will only continue to grow as this technology evolves. In the future, warehouses may be fully autonomous, operated by self-learning systems that can adjust to market changes and operational requirements in real-time. This transformation would be further supported by effectively integrating the latest technologies, such as the Internet of Things (IoT), blockchain, and 5G, enabling even greater visibility, speed, and coordination across the supply chain.

The Potential of Natural Language Processing in Warehouse Communication.

One branch of AI, Natural Language Processing (NLP), is helping to make warehouse communication more intelligent and efficient. NLP-powered voice-enabled assistants and chatbots can be easily integrated into warehouse management systems for hands-free operations. Workers can give verbal instructions and be directed towards an item, update stock records, or log a problem without having to consult a handheld device or computer.

Real-Time Demand Sensing and Adaptation

Real-time demand sensing for warehouses with AI, enabling warehouses to respond to current market signals in real-time. If a product, for instance, suddenly goes viral overnight, then AI can identify those growing spikes of interest and trigger the warehouse to prepare for receiving orders in the millions.

Application of AI in Reverse Logistics and Returns Management

Returns are one of the most common pain points in supply chain operations, especially in e-commerce. AI is also enhancing reverse logistics by optimizing the processes of return logistics, inspection, and restocking or discarding of items. Machine learning algorithms can identify the most efficient route for returns, taking into account item condition, resale potential, and associated costs. AI also helps understand the human behavior behind returns, using data analysis to spot patterns and recommend improvements in product descriptions, quality, and packaging. This reduces operational burden while improving customer satisfaction and minimizing waste.

AI Insights: Powering Up Supply Side Collaboration

AI isn’t only transforming internal warehouse operations, it’s also enhancing collaboration with suppliers. AI enables both parties to make better decisions more quickly by providing real-time visibility into stock levels, delivery schedules, lead times, and other relevant information. Predictive analytics helps forecast supply delays and offers alternatives to prevent bottlenecks. AI-enabled dashboards and shared data environments offer suppliers enhanced visibility into warehouse requirements, enabling more precise production and shipment planning. This transparency fosters and helps develop a more connected and efficient supply chain.

Responsible Warehousing and Ethical AI

Additionally, companies are responsible for utilizing AI to advance their environmental and social objectives. Responsible warehousing involves not just the technology you adopt to generate profit, but also the systems you build that are sustainable, inclusive, and accountable.

Conclusion

Warehouse Automation Solutions are revolutionizing commercial logistics, integrating intelligence and automation into logistics systems to make them faster, more innovative, and more responsive. AI is transforming every aspect of the warehouse and its operations, from inventory management and robotics to predictive analytics and sustainability.

Stay updated on the latest innovations shaping the future of warehousing and supply chains! Follow us on Facebook for more insights, expert tips, and industry news. Join our community today and be part of the revolution in smart logistics.