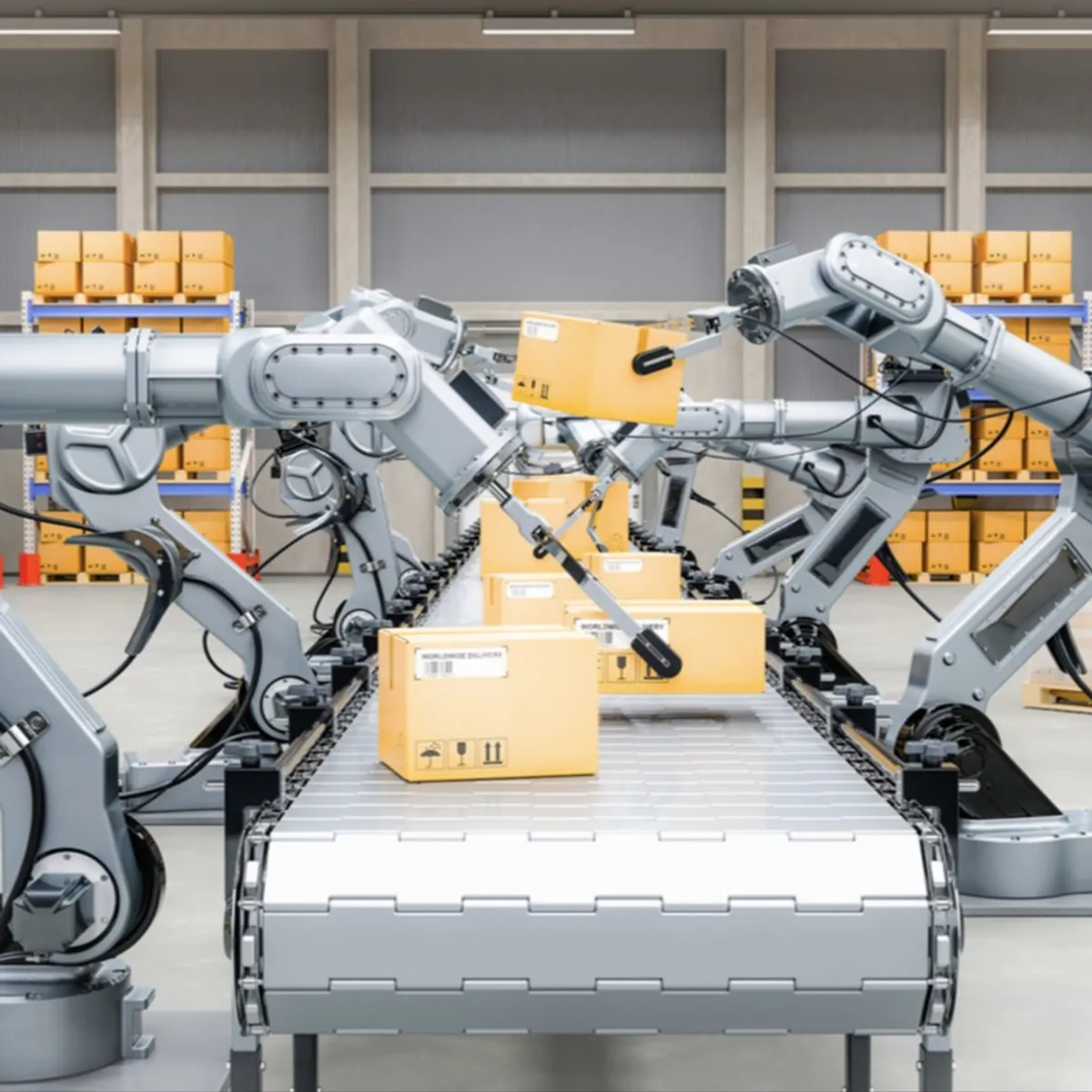

There is a shift in the warehousing business of the United Arab Emirates. What used to be heavily dependent on manual labour is currently being taken over by smart robots, artificial intelligence, and integrations to cover all the tasks, such as storage and picking, packing, and shipping. This change is a wider digital warehousing revolution, one that has the UAE as a frontrunner in supply chain innovation.

The meaning of Smart Warehousing.

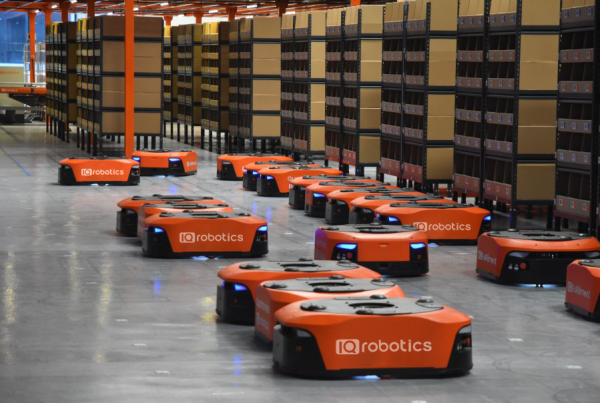

Smart warehouse extends beyond the conventional storage. It incorporates autonomous mobile robots (AMRs), automated guided vehicles (AGVs), sophisticated sensors, and warehouse management software to formulate smooth working processes. There are robotics companies in Dubai, such as IQ Robotics, that are already implementing robotic solutions that facilitate operations, enhance throughput, and accuracy. Smart digital warehousing implies fewer manual operations, improved processing, and more data to make decisions.

Why the UAE Needed This Shift

The UAE has a number of automation drivers. To begin with, the volumes of e-commerce have increased significantly, requiring quicker fulfilment of orders and greater accuracy of operations. Second, manual-intensive work processes are not sustainable due to labour shortages and increasing wages. Thirdly, the country’s emphasis on the digital economy and smart infrastructure is consistent with the implementation of robotics and IoT in the supply chain. A combination of these factors was the ideal scenario in which the revolution in digital warehousing could take place.

IQ robotics | Group of specialists making efforts to promote automation and technology

Robots have been introduced that can move freely down the aisles of the warehouse, collect and transport merchandise with little to no help. As an example, the AutoStore system implemented by Swisslog at one of the large distributors in the UAE employed robots on a grid system to store and retrieve goods and optimize storage layouts. Predictive analytics and IoT sensors are also used to monitor inventory, predict demand, and organize storage layouts.

Effects on Operational Efficiency.

Order-processing times are reduced, and the accuracy of the adoption of smart robots is enhanced. Certain systems in the UAE have almost perfect accuracy rates, which minimize returns and mis-shipments. The space used in warehouses is minimized through vertical storage and the robots to retrieve the items. Automated sorting and picking result in improved throughput and less labour load. All these transform digital warehousing into a cost centre into a strategic competitive edge.

Cost vs Value: Business Implications of the Same.

The adoption of automation includes initial capital expenditure, integration expenses, and change management. However, it has a price in the form of reduced labour overheads, reduced errors, quicker fulfillment, and the resultant affordability of scaling operations. In the case of businesses in the UAE, the ROI is the increased service levels and customer satisfaction in the long term, as well as a supply chain that was developed to grow and not merely maintain stability.

In the UAE, intelligent warehouses help accelerate local fulfilment and distribution to the region. In the case of firms that export to the Middle East or other parts of the world, Warehouse Automation in UAE makes the firms competitive. It enables them to handle orders in a short period of time, complex zoning, and multinational compliance. Differently put, a warehouse fitted with smart-robots in Dubai is not only local- it is global-oriented.

Scalability and Sustainability

Complexity, which an increased number of users can support without impacting the system’s resources, is known as scalability. Scalability complexity, that is, that can be support an increased number of users without affecting the resources of the system, is referred to as scalability.

Since volumes increase, automated systems scale better than manual systems. The robots will be available 24 hours, and they will be able to cope with peaks such as promotional spikes and adjust their product mixes. Simultaneously, effective plans, accurate picking, and dynamic pathways save energy and waste, which makes operations more sustainable. The smart logistics initiative by the UAE is in line with all the national sustainability and innovation objectives.

How to pick the appropriate Smart Warehouse partner.

Questions to ask a partner when assessing them to automate in the UAE: Does the partner provide modular robotics and scalable infrastructure? Do they fit with your current warehouse management system? Do they offer quantifiable accuracy and throughput benefits? Do they support your growth strategy? With the provider, ensure that he or she is able to expand with your business and not hold you to the old technology.

Conclusion

This increase in smart robots in the digital warehousing industry in the UAE will mark a new age. Those businesses that have adopted digital warehousing automation are not just enhancing efficiency and accuracy, but they are redefining the concept of supply-chain excellence. To the companies that have to act within the region, the message is simple: digital warehousing ceases to be a back-office operation. It is a competitive facilitator of expansion, responsiveness, and customer contentment.

Get in touch with Contact IQ Robotics to get a custom consultation, or follow us on LinkedIn to know more about the future of automation in the warehouse.

Frequently Asked Questions

1. What would you suggest to enhance my warehouse management in the UAE using automation?

Robotics and AMRs used in digital warehousing are more accurate, faster to process, and require fewer labour. An appropriate automation service provider assists you in scaling operations and seasonal peaks to be more effective and resulting in your 3PL or in-house facility being more competitive.

2. What types of robots are widespread in warehouses in the UAE?

Such typical solutions are autonomous mobile robots (AMRs), automated guided vehicles (AGVs), robotic picking systems, and sensor-driven sorters. The warehouse management solutions incorporate these tools to automate the storing, picking, packing, and shipping processes.

3. Do large companies only find warehouse automation to be cost-effective?

Not necessarily. Though big business benefits from the large type, there are now mid-sized business modular automation options. The UAE companies are achieving the ROI through the decrease in labour expenses, the minimization of mistakes, and accelerated satisfaction. The trick is to select scalable and flexible systems.

4. What are the sustainability advantages of automated warehousing?

Automation helps to achieve sustainability by consuming less energy (by laying out the process optimally), less waste (by reducing the number of errors and returns), and 24/7 work (maximising utilisation of assets). Automation is in line with the larger objectives of smart infrastructure and sustainable industry of the UAE.

5. What is the best way to locate a partner to do smart warehouse automation?

Find a partner that has experience in the UAE market, demonstrated robotic and software solutions, and will be able to integrate with your existing systems. They need to deliver quantifiable performance benefits, be scalable, and be aligned with your expansion plan as opposed to locking you into an ad hoc setup.