Introduction

Logistics has long served as the lifeblood of global trade, that complicated mix of businesses that move goods from point A to point B. But the fact is, old-school warehousing often bogs down in inefficiencies, a labor shortage and that perennial demand from consumers to get products more quickly. Enter robotics warehousing automation in UAE, a gamechanger in the face of the way modern logistics should be approached. Call it the industrial revolution of supply chains, where machines not only help workers; they enable them.

Understanding Robotics Warehousing Automation

What is warehousing automation?

At its base level, warehousing automation is about heavy machinery, robots, smart systems and more that make it so humans no longer have to do the mundane, routine tasks — picking, packing, moving, storing inventory and the like — by hand. Under these latter-day autocrats, workers no longer slalom miles-long aisles for their wares; robots perform their tasks with superior speed, precision, reliability.

The Robotics in Warehouse Industry

Automation isn’t brand new. So yesterday with the conveyer belts and the forklifts. But then came smart robotics, and the game of simple mechanization upgraded to smart robotic automation. The first robots were rigid and stuck to paths. Today’s robots are becoming more fluid, more mobile, A.I.-powered machines that are learning to think about their learning in the moment, and to produce a response.

Key technologies driving automation

What robotics warehousing is made of AI Machine vision IoT Machine learning Together, these technologies enable robots to not only move goods, but also recognize patterns, anticipate demand and expedite throughput.

Key Benefits of Robotics in the Warehouse

Increased efficiency and productivity

A tireless workforce, one that doesn’t need a break, that works 24 hours a day. That, in short, is the promise robots offer warehouses. They save time on picking, when people aren’t doing anything, and they keep things moving.

Cost reduction and ROI

Robotics systems may not be cheap, but you’ll be glad you have them once things get rolling. Companies reduce labor costs, errors and speed up throughput. Many businesses get their investment back in just a few years.

Better precision & reduced risk of mistakes

Warehousing errors can prove expensive. From accidentally shipping the wrong product to slapdash record-keeping, such mistakes can quickly snowball. With robotics this is very much restricted through specific algorithms that the errors are minimized and the barcodes are scanned.

Safety improvements for workers

A shift that is heavy, repetitive or hazardous for human employees. By turning these tasks over to robots, companies make their workplaces safer and liberate humans to do more supervisory and creative work.

Versatility of Robotics Systems in the Modern Warehousing Landscape

Automated Guided Vehicles (AGVs)

AGVs are like robotic forklifts. Navigation They commute along established paths to transport loads between warehouses, saving time by eliminating the need for manual transport.

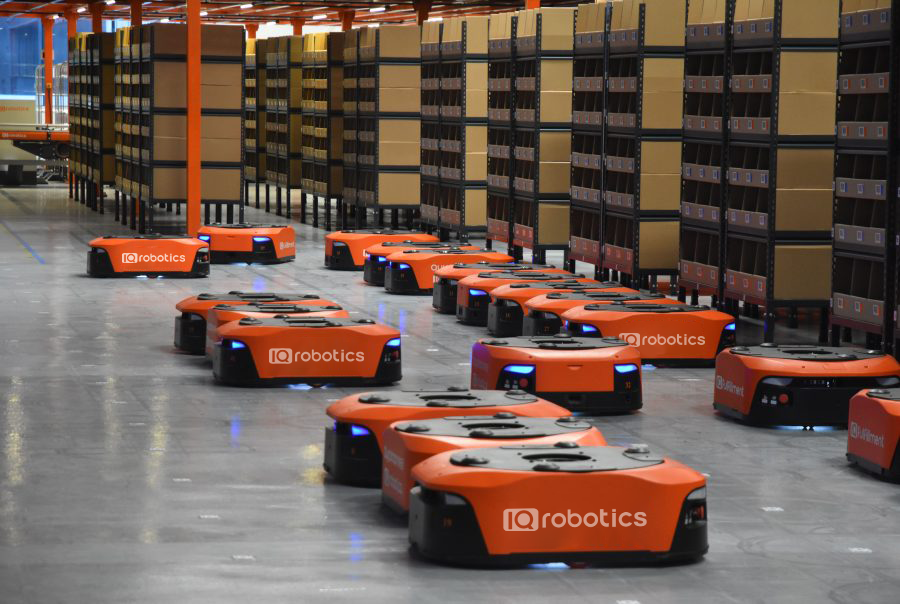

Autonomous Mobile Robots (AMRs)

AMRs do not need a static path, which is not the case for AGVs. They are based on sensors and mapping system so they can be operated autonomously in the warehouse, for maximum flexibility in dynamic environments.

Robotic arms and pickers

Precision work, such as picking up delicate objects or building packages, is an ideal skill for robotic arms. A complex gripping system allows also the handling of non-symmetric products.

Conveyor and sorting systems

Sure, conveyors may sound old hat, but when combined with a cutting-edge AI-powered sorting system, they’re whizzing through the job of sorting the tens of thousands of parcels an hour they’re being fed with uncanny accuracy.

Drone-based technology in warehouse functions

Inventory checks. Drones are entering warehouses to confirm that yes, we do have the screws we need. Instead of climbing ladders, or shutting operations down for the day to do inventory, drones can scan bar codes and deliver data in minutes.

How Robotics is Transforming the Way Logistics Works

Real-time inventory management

Warehouse stocks can be monitored in real time with the help of automation. Robots and scanners and sensors have been working ‘round the clock to ensure that databases are forever up-to-date so businesses always know, to the individual product, what they have on hand.

Order fulfillment speed

Today, people expect same-day or even same-hour delivery. DONE RIGHT, robotics can accelerate order picking and packing for a business that has to keep up with such demanding schedules, exclusive EFTM testing reveals.

Last-mile delivery optimization

For all of robotics’ inside-out vision, services like delivery drones and autonomous cars are pressing automation out to the last mile of deliveries, in some cases reducing delays and expenses.

Intersection with AI and IoT

With AI and IoT, the warehouse is a smart ecosystem. Logistics companies are now working on a level of efficiency which the world has never previously seen, through the use of predictive analytics, machine-to-machine (M2M) communication, and real-time decision-making. Problems of Robotics Warehousing Automation Single robot localization and mapping Problem (SLAM), which is where an intelligent mobile robot can automatically explore its own location-redress in the work environment, or a method by which the robot can generate an individual map of the warehouse field, is necessary since there are high demands on delivery accuracy and delivery efficiency.

High initial investment costs

Robotics automation systems don’t come cheap. It’s expensive to invest in, require training and support, and not an easy task to get up and running, especially with small or medium business.

Workforce issues and training requirements

Workers may worry about losing their jobs to robots. However, robotics warehousing automation in UAE is also generally associated with the creation of new jobs in supervision, maintenance and programming. Closing this gap will require education.

Cybersecurity and data concerns

A smart warehouse is an interconnected warehouse. But connectivity also means risk of cyberattack. There are issues related to protecting your data, and ensuring that systems communicate in a trustworthy manner.

Maintenance and scalability issues

Robots need constant upkeep. Second, rolling out automation to multiple sites/organizations should happen through SDLC instead of research-grade scripts.

Application of Robotics in Logistics

Amazon’s robotic warehouses

In its fulfillment centers, Amazon has tens of thousands of robots. Carted robot bring shelves of products to human workers and reduce the time spent walking and time spent gathering in order.

DHL’s automated facilities

DHL has already introduced picking and sorting with robots – with the help of robotics, it has reduced the turn-around times and brought the smile on the face of the customers.

Walmart’s fulfillment centers

#Walmart applies robotics and AI to e-commerce distribution centers, cutting costs and efficiently scaling in the lead up to seasonal peaks.

The Future of Logistics Robotics

AI and machine learning’s role

The future will belong to smarter robots, not the ones that follow orders obediently but will be ones that are more intelligent that can take decisions, can learn from events and government activities that take place and can actually predict human needs before it knows that actually it needs it and “monitors what is happening to it and it processes all this information and this is both data as it can take decisions based on this.

Supply chain predictive analytics

If companies link robotics technology with predictive analytics, they can prepare for spikes in demand and automatically adjust the inventory amount.

Sustainable and green warehousing automation

Robots can play a role in greening warehouses, such as by conserving energy, reducing waste, and enabling green work practices.

Conclusion

Robotics warehousing automation isn’t a mere fad — it’s a seismic shift. And as the examples above illustrate, in the modern logistics industry, robotics is a superior model for moving material, and is far better at increasing efficiency, reducing costs, enhancing safety and fulfilling customer needs. While there may be problems in the level of investment and concerns in terms of labor, there are more pros than cons to an early date for the funding. In the next phase, we’ll work with the robots alongside us; they’ll bring speed and precision and endurance to a task, and we’ll contribute our creativity and supervision. Together, they will develop a logistics infrastructure that is faster, smarter and greener.

Looking to transform your supply chain with smarter, faster, and more reliable solutions? Discover how robotics warehousing automation in UAE can boost efficiency, cut costs, and future-proof your business. Follow us on Instagram for real insights, success stories, and the latest innovations in warehouse automation. Let’s build the future of logistics together!