Introduction

The national strategy of the United Arab Emirates (UAE) is to act as a gateway for international trade between the East and the West. The UAE has an expanding e-commerce sector, increasing import-export volumes, and an availability of infrastructure that competes with the best in the world, so there is a mounting demand to maximize warehouse functionality. But the old school manual processes frequently do not meet increasing customer demands for efficiency and accuracy. This is where warehouse robotic automation in UAE comes in, changing the game of supply chain, and the way goods move.

If you’ve ever asked yourself why every top robotics company in Dubai is racing to roll out automation, intelligent systems and robotics in their warehouses, you’ll find the answers in this blog. Let’s discuss the key benefits of Warehouse Automation in the UAE, the technologies that are driving it, and what the future holds.

Understanding Warehouse Automation

What is warehouse automation?

Warehouse robotic automation in UAE is the use of robotics, artificial intelligence and digital technologies in managing and picking goods. Machines and AI don’t just eliminate huge amounts of mindless work but are getting faster and easier to work with, fewer mistakes are made and better results are within reach.

Emerging technologies powering automation in UAE

The most common technologies in use are Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), robotic arms, drones, Warehouse Management Systems (WMS) driven by artificial intelligence, and advanced conveyor systems. These are tools for the UAE to remain in line with international logistics practices.

Manual vs. automated warehouses

A manual warehouse has been facing bottlenecks, labor shortage and human errors; however, there are a lot of warehouses in the world. Instead, an automated warehouse functions efficiently, precisely, and fast — fulfilling thousands of orders each day without significant hiccups.

The UAE’s Logistics Landscape

Strategic geographical location

As a global transport and trade hub situated at the confluence of Asia, Europe and Africa, the UAE has a unique vantage point. Jebel Ali’s ports and Dubai and Abu Dhabi’s logistics zones require warehouse facilities that are a match for the world’s largest logistics organizations and local logistical demands —erudite and substantial.

Ecommerce hub UAE

Online shopping has taken off in the UAE, where the likes of Amazon, IQrobotics have set ambitious standards of very rapid deliveries. Automation means orders are processed fast enough to keep up with consumer needs.

Government enabling measures for smart logistics

The digital transformation is being actively facilitated by UAE government. So-called public initiatives like Dubai’s “Smart City” blueprint and Abu Dhabi’s “Industry 4.0” push is forcing companies to adopt AI, IoT, and automation to stay in the game.

Benefits of Using Warehouse Automation in UAE

Enhanced operational efficiency

Automation reduces the monotonous manual work down to a minimum and makes it possible to run warehouses 24/7 without disruption. Robots can move goods, stock shelves and even pick items faster than human workers, streamlining tasks.

More precise with fewer errors

Mistakes in supply chain can erode customer trust and results in expensive returns. Automated systems make such errors dramatically less common, guaranteeing that inventory counts and parts shipments remain accurate.

Quicker order deliveries and higher customer satisfaction

The UAE’s customers now demand same-day or even two-hour delivery windows. Warehouses depend on automation to fulfill big volumes of orders so they can ship them ASAP, leading to increased customer satisfaction.

Save Money and Get Good ROI

Although it does need this investment in the beginning, the long-term ROI is huge. Reduced labor, aligned data, and optimized workflows deliver savings in the millions to business across all industries.

Scalability for future growth

Additionally, many companies in the UAE experience peaks of demand at certain times of year – such as Ramadan, Eid, and shopping festivals. Automation warehouses can fairly quickly ramp up their operations to deal with peak loads, with little to no disruption or downtime.

Security & minimization of workplace dangers

Robots prevent office injuries by doing heavy lifting, repetitive tasks and working in dangerous conditions. It’s a way of keeping warehouses safer, while human workers concentrate on overseeing the machines and problem-solving.

Real-time inventory visibility

Intelligent systems offer real-time information on inventory, order status, and warehouse productivity. Managers can then use this real-time visibility to out-of-stock/over-stock inventory risk.

Popular Types of Automation in Warehouses in the UAE

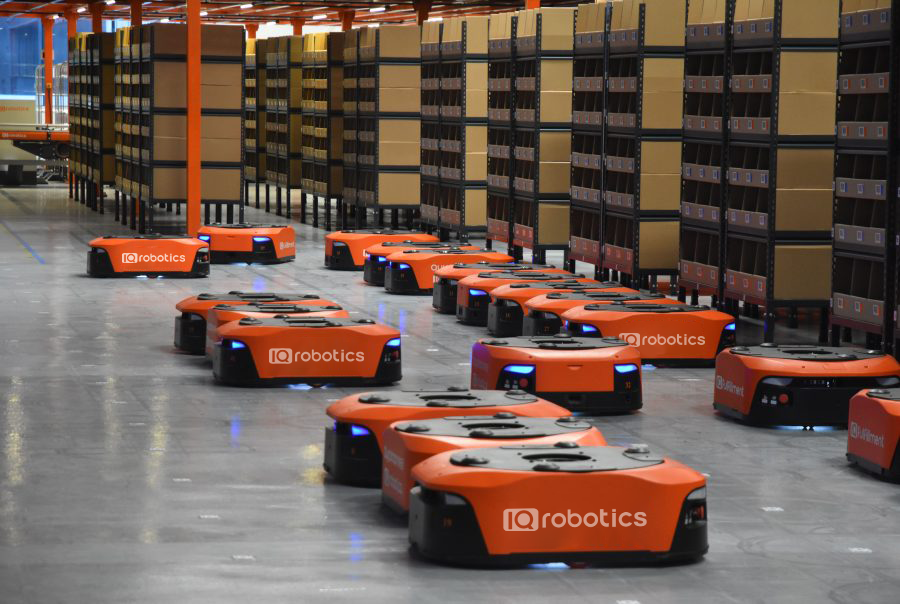

AGVs (Automated Guided Vehicles) & AMRs (Autonomous Mobile Robots)

AGVs move along predetermined paths for carrying materials; AMRs dynamically respond to warehousing environments. They reduce manual transport requirements while enhancing flexibility.

Robot picking and packing

Robotic arms can be kitted out with AI and machine vision to pick, pack, and handle fragile items with minimal damage and increased order accuracy ratios.

AI in Warehouse Management Systems (WMS)

AI-powered WMS collates multiple data sources to streamline picking paths, levels of stock and overall warehouse efficiency.

Drones for inventory management

Drones can read barcodes and take stock without closing down warehouse operations, which saves both time and labor.

Conveyor and sorting systems

Automated belts equipped with AI-driven sorting technology handle thousands of packages an hour, ensuring swift shipping.

Cautions While Using Warehouse Automation in UAE

High upfront investment costs

Automation is expensive to set up, This can be challenging for SMEs, but financing options and government support are helping to ease adoption.

Workforce training and resistance

Workers can be reluctant to adopt automation out of fear of job loss. Companies need to consider training programs to retool employees as technicians and supervisors.

Maintenance and technical expertise

Material handling systems need to be watched constantly and maintained by well-trained crew members to operate efficiently, and that’s difficult to arrange for those who may not have local sources for expertise.

Cybersecurity and data risks

Linked warehouses can fall prey to cyberattacks. Ensuring the security of systems and safeguarding delicate logistics information are major focus areas for businesses in the UAE.

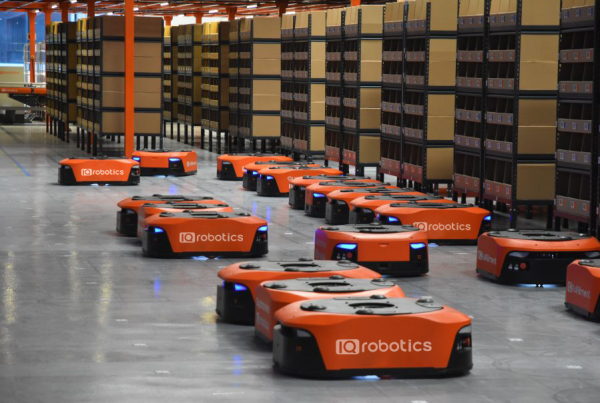

Case Studies: UAE Leaders and IQ Robotics’ Role

Global giants like Amazon UAE and DP World have already proven how warehouse automation can transform speed and efficiency in logistics. But automation isn’t just for multinationals.

At IQ Robotics, we bring the same world-class robotics, AI-driven WMS, and automation tools to local UAE businesses, from SMEs to large retailers. Whether it’s scaling during Ramadan and Eid peaks, cutting order errors, or enabling faster last-mile delivery, our solutions help companies compete at the same level as global players.

By aligning with the UAE’s Smart Logistics vision and supporting both free zone operators and e-commerce brands, IQ Robotics is powering the next wave of warehouse automation in Dubai, Abu Dhabi, and beyond.

Warehouse Automation in UAE is the Future

AI and predictive analytics for more intelligent warehouse

(AI-driven analytics will predict consumer demand, optimize inventory and forecast supply chain disruptions — making warehouses smarter than ever.)

Integration with sustainable logistics

The U.A.E. is working toward greener methods. Automated warehouses systems will make a significant contribution to lower levels of energy consumption and reduced carbon footprints through the efficient operation of their logistics systems.

Human-robot collaboration in UAE supply chains

In the future, humans and robots will work along side by side — robots will do the speed and precision work and humans will bring creativity and oversight.

Conclusion

Automation in warehouses in the UAE is becoming less of a luxury and more of a necessity. From efficiency and accuracy to safety and scalability, businesses that adopt automation stand a better chance of meeting the world’s logistics demands. Backed by government programs and driven by a thriving e-commerce sector, UAE warehouses are quickly adopting robotics, AI, and smart technologies. It’s no secret what the future holds with automation taking center stage to help position the UAE as one of the world’s most advanced logistics centers. Companies who implement automation today will not just do well but excel in the competitive global market.

Ready to take your logistics to the next level? Discover how warehouse robotic automation in UAE can streamline operations, cut costs, and boost accuracy like never before. Follow us on Facebook to explore success stories, automation tips, and the latest innovations shaping the future of smart warehousing.