A fast and accurate logistics system has become a success. In the UAE, organizations are resorting to robotics warehousing automation to address increasing demand and counteract challenges. These advanced facilities have robots that deal with storage, picking, and dispatching, which cannot be controlled by humans. The new model of lights-out warehousing is a significant change in the logistics of working in the region.

In some of the industrial zones, such as the south of Dubai and the industrial zones of Abu Dhabi, automation is transforming the way goods are transported daily. The driving force of this change is through the provision of smart, scalable automation solutions by IQ Robotics, which realize faster and more accurate fulfillment. Robots are 24/7, maintaining the efficiency and cost-effectiveness of operations. Firms in the GCC are still investing in such innovations to develop smarter and future-ready supply chains, defining the concept of efficiency in today’s warehousing.

IQ Robotics Is Redefining Smart Fulfillment in the GCC

Overview

They are at the top of the automation revolution in the UAE, turning the traditional warehouses into smart, robot-driven spaces. The company is one of the regional automation leaders in robotics that combines hardware, software, and AI to provide scalable and fully connected fulfillment ecosystems. It has a very simple but ambitious objective: it seeks to redefine the way products are stored, transported, and delivered by regional businesses.

Key Offerings

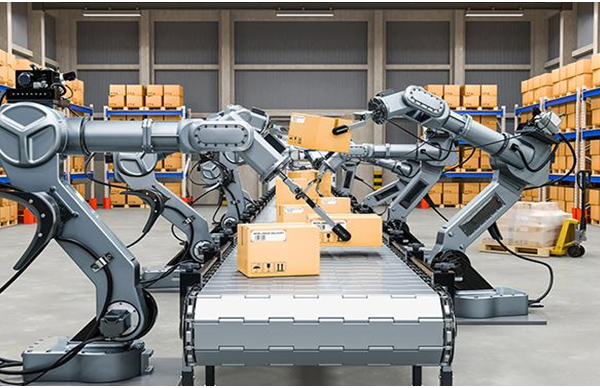

• Offers robotic pick and sort solutions to streamline fulfillment and eliminate labor reliance.

• Provides conveyor and DWS systems, which automate weight, measurement, and goods transfer.

• Provides AI-based software solutions, such as WMS, OMS, and TMS, to control the central warehouse.

• Makes sure the design and integration are customized to encourage easy integration of automations in the current facilities.

• Enables 24 hours of operation and predictive maintenance and scales fleets of robots.

Why It Stands Out

They are also a pioneer in the innovation of logistics in the UAE, as the provision allows warehouses from Dubai to Riyadh to operate with near-zero downtime through intelligent automation based on data.

Find out more about the high-level automation technologies of IQ Robotics.

How Automation Helps a Sustainable Future in Warehousing

Automation is increasingly becoming vital in minimizing wastage and energy use; sustainability is assuming a key business strategy. Lights-out warehousing in the UAE is in line with the green logistics strategy of the country by maximizing the use of power, reducing errors, and reducing the number of materials. Smart robotics is the guarantee of productivity without environmental irresponsibility.

With the UAE building a track record of becoming a logistics powerhouse, robotics and warehousing automation are making a transformation that has never been seen before. Free zones, such as JAFZA and Dubai South, invest a lot in automation infrastructure, which enables the logistics companies to satisfy the regional and international demand more effectively. To businesses, automation is not simply a technological upgrade, but rather it is a requirement in order to be able to compete in the rapidly changing GCC supply chain.

Smart Automation Supporting Green Logistics

Smart automation is a way to make warehousing less harmful to the environment, as it decreases wastage and enhances energy efficiency. Automated systems have sensors and data that control lighting and temperature as well as power consumption so that the resources are not wasted. The practice will reduce carbon emissions and generate a cleaner and greener work environment.

Most warehouses in the UAE are changing to environmentally friendly operations by automating their processes. Through smart robots and computerized systems, businesses save on paper, fuel, and delivery routes. These minor yet effective transformations ensure that logistics are cost-efficient and sustainable, which embraces the long-term environmental objectives of the UAE.

The Power of Independent Warehouse Operations

Overview

The idea behind lights-out warehousing is that it relies on completely autonomous systems that can do all the work in the warehouse. These warehouses are based on modern robotics, AI, and analytics to streamline warehouse activities like storage, picking orders, and shipping. The outcome is a self-regulating environment, which operates 24/7 with accuracy and a low error margin.

Key Offerings

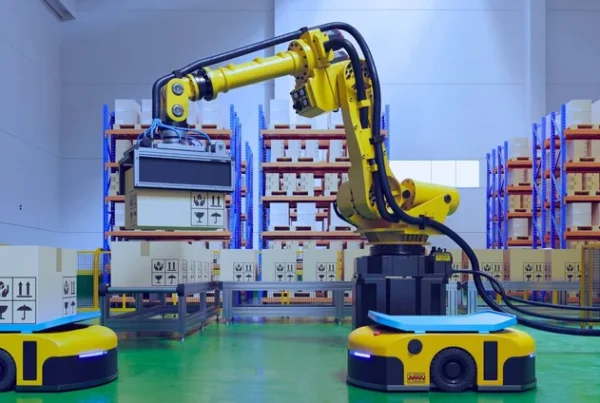

• Operates AI-powered robots that perform tedious warehouse operations such as sorting and moving merchandise.

• Provides real-time inventory management and accuracy of operation with data.

• Provides automated guided vehicles (AGVs) to travel safely and accurately within the layout of a warehouse.

• Includes sensor-based obstacle detection and uninterrupted workflow systems.

• Provides patient continuity, and machine learning ensures demand forecast and flow optimization.

Why It Stands Out

The integration of robotics and smart data analytics enables autonomous operations to enable the GCC businesses to improve speed, consistency, and profitability, which will make lights-out warehousing a competitive approach and not a vision of the future.

Conclusion

The lights-out warehousing path is not a mere vision anymore, but it is taking shape as the new benchmark in logistics excellence. Robotics warehousing automation is also transforming firms across the UAE and the GCC as a whole to realize the limitations of human beings and ensure greater accuracy, quicker delivery, and sustainability.

Robotic automation will continue to be a pioneer in the Middle East as demand for faster and more efficient solutions becomes the norm. In AI-powered platforms to complete autonomous fulfillment centers, the change has already started, and they are at the head of this transition.

Get in touch with Contact IQ Robotics to get a custom consultation, or follow us on LinkedIn to know more about the future of automation in the warehouse.

FAQs

- What is lights-out warehousing?

Lights-out warehousing is a completely automated warehouse with robotics, artificial intelligence, and sensors. Such systems are accurate, fast, and efficient 24/7, and also labor costs are greatly minimized. It is an emerging trend in the logistics business sector in the UAE.

- What are the benefits of robotic automation of the warehouse?

Robotisation of automation speeds up the order-processing speed and accuracy due to its machine reliability. It reduces the downtime, minimizes inventory management, and increases the fulfillment speed. This will lead to increased speed of delivery and customer satisfaction.

- Which technologies are used to support lights-out operations?

The lights-out warehousing systems are based on AI, machine learning, and robotics. High-tech WMS, TMS, and IoT sensors collaborate to organize all the movements inside the facility. The technologies allow real-time communication among robots.

- What is the need for automation in logistics in the UAE?

The logistics centers in the UAE have huge volumes of trade that require efficiency and reliability. Automation will guarantee scalability, compliance, and cost savings among companies. It also brings about sustainable growth due to the minimization of energy wastage and reliance on manual labor.

- Why select IQ Robotics in the GCC as a means of automation?

It is a company that focuses on robotics warehousing automation and has successful regional experience. Its solutions combine the newest technology, AI, and hardware to make a transformation in the warehouse. The company is trusted by the UAE businesses because it is credible in the delivery of reliability, scalability, and innovation at all levels.