Warehouses throughout the region now confront surging demand and tight delivery targets. Lots of Websites resort to robotic automation to cope with this immense growth. These tools allow teams to work faster and more safely. They are also used for continuous flow during periods of peak demand. And as a greater range of industries grows, automation is the norm in daily warehouse life. The change has radiating implications about how teams store, track, and move goods.

Increasing Pace of Everyday Operations

Most warehouse teams still have speed as a top priority. Robotic automation can help reduce lengthy manual steps. Robots gently convey goods. They aid staff during peak hours. “That makes every shift more predictable. Tasks get completed more quickly now. Errors are also extremely low due to the automation. This secures orders and inspires confidence. As the market expands, speed is even more crucial.

More accurate and uniform flow

Precision is the guiding principle throughout the supply line. Robots follow clear steps. They minimise simple errors and lags. This control aids teams in hitting their daily targets. It also renders fragile items safe from damage. Robots move with a stable rhythm. This rhythm paves a clear road between storage and shipment. Clear flow supports higher volume. The peak demand is when teams have more influence.

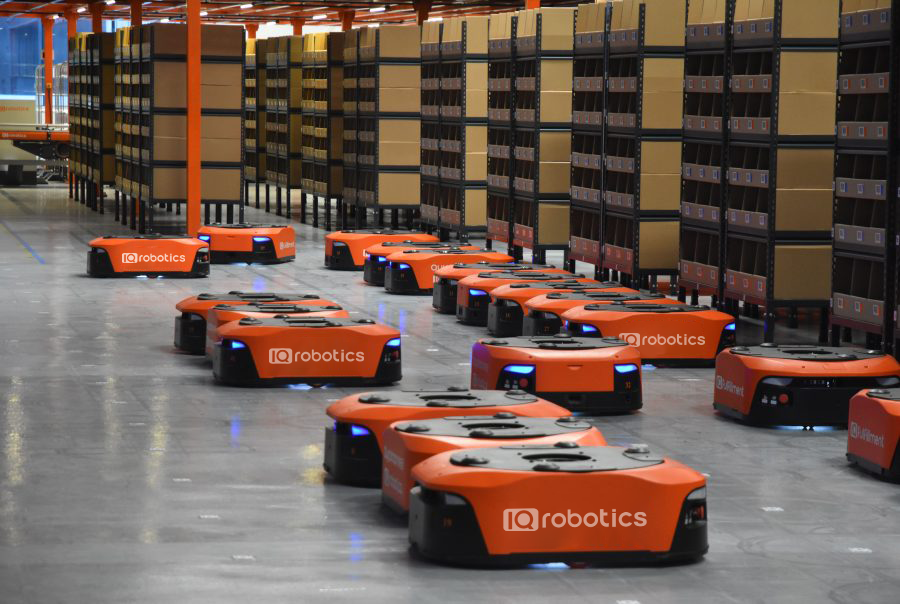

Using Warehouse Automation Robots

Robots are now an important component of many storage zones. Warehouse automation robots granted immunity to all items via the space between aisles. They hoist loads that once required many workers. This means that staff are then available for problem-solving tasks. Robots have memories, too; they learn from previous runs. E) They choose better paths each night. This lesson is useful for helping teams handle larger orders. With the region expanding, robots will play an even bigger role.

Better Tools with Warehouse Robotics Tech

And new digital tools are teaching robots to navigate their steps. Warehouse robotics technology enables robots to scan shelves and track goods. These tools read labels fast. They also communicate updates to control systems. This is easy to read and follow. Managers are able to see the stock levels in real time. Restocks are less stressful to plan. Smart tools also help teams anticipate demand. This helps the sites stay prepared for busier weeks.

Improved Safety for Workers

Safety should guide every warehouse. Robots help reduce risky tasks. They lift heavy weights with sustained power. They can make their way across confined floors as well. This reduces the risk of injury to staff. Robots make challenges safe for teams. Safe work zones improve morale. They also support long-term stability. And many companies are now modifying floor plans to keep both people and robots safe.

More Flexible Warehouse Design

Robotic automation allows teams to utilise SpaceBetter. Robots move with clear routes. This means less shall be required for wide aisles. It also provides additional space for storage. Time is a robot path at many sites. This shape modification is conducive to rapid relocation. It also shortens travel time through the floors. Adaptable design makes it easy for teams to grow. As demand ramps up, decisions about layouts can be made with less anxiety.

Strong Growth Benefits from Robotic Automation

Today, many warehouses overhaul operations based on new tools. The fast-growing region needs stable systems. Robotic automation – naturally and easily handles high volumes. It enables teams to meet tight deadlines. It also protects stock quality. “When you move to automation, you increase resilience. And it preserves the gushes that occur, even when the staffing comes and goes. This support eases businesses’ planning for long-term growth.

Quick Access When Picking and Packing Orders

Order picking used to take hours and hours. Robots now cut this to an absolute minimum. They reach shelves quickly. They also follow direct routes. This improves picking accuracy. Packing becomes faster, too. Robots deliver goods to packing stations with precise timing. This timing minimises wait time for employees. The complete order cycle is now also shorter. This is why warehouses can see more orders come through each day.

Real-Time Data Improves Planning

Robots immediately share data with control systems. These changes allow teams to see problems early on. Managers adjust plans in minutes. The warehouse itself remains stable with real-time data. It even makes all future shifts better. Data reveals weak spots in the flow. It helps teams fix them fast. This provides a solid foundation for future growth.

What The New Plan Means For Automation in the UAE

There will be more automation in the region to come. Trade needs more effective tools. Robots will do more of the things that we do each day. AI will determine their decisions and paths. Warehouses will grow smarter and safer. Processes will become streamlined and transparent. A growing number of teams now install upgrades gradually. This avoids major interruptions. It offers to aid teams in taking on new systems quickly.

Conclusion

Automation is redefining the whole shape of warehouse life. It’s low speed, high safety, and moderate growth. Robotics Automation will usher in the next phase of logistics for this region. It will empower teams to act with control and confidence as the demand increases. With the right tools, warehouses can expand without sacrificing speed or quality. Automation will increasingly carve out a robust way forward.

Sign up at IQ Robotics to get a customized consultation or visit us on LinkedIn to get to know more.

FAQs

1. Do robots actually take human jobs in warehouses?

Robots assist employees and take on the heaviest work, but there remain key areas for humans to monitor.

2. Does automation raise warehouse speed?

Yes, it’s a time saver and workflow enhancer.

3. Are robotic warehouses safe for workers?

Yes, robots reduce injury risk by doing the dirty work.

4. Does robotic tech improve accuracy?

Sure, it cuts down on errors and helps ensure stable moving.

5. Are warehouses going to require large-scale makeovers for the robots?

A few updates are helpful, but many tools fit into current layouts.