The logistics business is being upended, and the center of this transition is Robotics Automation in Supply Chain. No longer the things of science fiction, robots are transforming into critical tools for improving operational efficiencies for utilities. Across the supply chain, from the warehouse to last-mile delivery and into the ever-growing demands of global commerce, robotics is transforming businesses.

Robotics in the contemporary Supply Chains

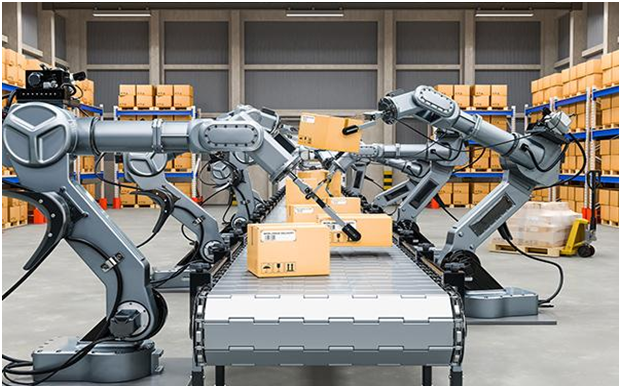

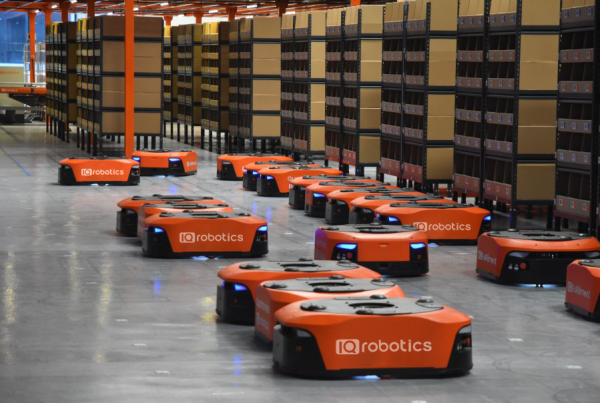

Warehouse automation is already a familiar part of many operations, where robots take care of sorting, picking and packing. These are machines which work next to people which take away repetitive work of doing manual labor and helps to accelerate throughput. “E-commerce is growing, our customers’ demands for rapid turnaround are increasing, and robotics give us an opportunity to be competitive and also be accurate,” he said.

Driving Efficiency and Accuracy

One of the biggest strengths of robotics automation is that it minimizes mistakes. Robots do tasks without faltering, unlike manual processes which may cause less error when fulfilling orders. This not only increases customer satisfaction but helps to reduce returns. Robots also make efficient use of space inside warehouses, as they travel through narrow aisles and can operate around the clock, basically enhancing productivity without escalating labor expenses.

Integration with Artificial Intelligence

Now, the next wave of robots in supply chain management is not just about automation. Robots, with their machine learning algorithms, are learning to adapt, predict and act (through decision theory). Robots powered by AI can also detect inventory trends, predict demand, and even react when a supply chain is unexpectedly disrupted. This combination drives smarter, more agile supply chains to respond dynamically and in real-time.

Transforming Last-Mile Delivery

The final-mile delivery continues to be among the most difficult and costly in the supply chain. Now robotics is preparing to redo this phase with self-driving cars and delivery drones. These developments are aimed at faster and more sustainable delivery, especially in urban locations where both traffic congestion and cost remain persistent barriers. Regulatory and infrastructure challenges notwithstanding, the trend toward robotic delivery is a force to be reckoned with.

Human and Machine Collaboration

While automation raises fears of job displacement, the future is less replacement than collaboration.” Robots are good at dull, repetitive work while letting humans focus on strategic, critical thinking jobs. This adjustment has positive effects; for not only does it increase efficiency, but can also be dictated in terms of a safer working environment, in which physical labor is limited or potentially dangerous conditions are avoided.

Robotization and Sustainability in Supply Chains

Sustainability is at the heart of global industry, where robotics is helping to cut waste. Robots reduce waste not only through more precise inventory management but also by enabling efficient energy usage. Machine learning optimizes packaging, minimizes material overuse, and even maps smarter transportation routes. By combining efficiency with eco-friendly practices, Robotics Automation in Supply Chain is playing a key role in building greener, more sustainable supply chains.

Cost Savings Through Automation

The cost of robotics is high at first, but in the long run they offer substantial savings. Robots do not get tired and can work 24/7 with the less number of overtime costs and loss for mistake. The costs of maintenance are usually not much less than the cost of accidental human incompetence or inefficiency. When technology’s costs are available to the masses, small and mid-sized industry will also feel that robotics are cost-effective.

Data in Robotics Operations

Robotic automation is not just about physical chores, but data as well. Today’s robots come with sensors and communication tools that monitor data, process it and transmit analysis back to us. This data-led approach allows businesses to measure stock levels, review performance, and predict demand more accurately. Integration of data between robotics and supply chain management systems provides clarity and the ability to act on information to drive better decisions.

Overcoming Challenges in Adoption

However, adopting robotic solutions involves many challenges, in addition to its benefits. Barriers of initial investment, interfacing with the installed systems, and training employees are some negative consequences. For small firms, execution may be challenging without proper planning. Yet, with scalable robot solutions and government initiatives promoting digital transformation, these barriers are slowly breaking down. This shift is empowering more industries to embrace Robotics Automation in Supply Chain, unlocking new opportunities for efficiency and growth.

Impact on Trade and Logistics Globally

With supply chains transcending borders, robotics automation is also transforming global trade and logistics. From automated ports and robotized cargo handlers to artificial intelligence-driven customs processes, bottlenecks in global shipping are being eased. Robotic Infrastructure – Advancing Nations as Logistical Giants Nations that are investing in robotics companies in Dubai as infrastructure are making a play to be the logistical world leader. This global shift emphasizes robotics as more than tech trend but as an economic driver for growth and competitiveness.

Robotics for Cold Chain Robotics

The development of industries like pharmaceuticals and fresh food delivery has added an extra value to cold chain logistics. When it comes to temperature-sensitive products such as foods and other commodities, robotics is a critical element to the care in which they are handled. Such automated systems not only can track temperatures in real time, but can also monitor stock rotation and help reduce human error — key when dealing with perishable goods or vaccines that must be kept within a very specific temperature range.

Enhancing Worker Safety

Workplace safety is being overhauled by robotics automation as well. Warehouse and distribution centers workers often face risks of heavy lifting, repetitive strain, and unsafe environments. Robots are taking care of these physically demanding jobs, lowering the risk of injury and overall safety. It makes for a healthier environment by allowing human workers to work in jobs that require critical thinking and problem solving.

Personalization and Customer Experience

In an era of consumerism, customization is beginning to be anticipated, rather than seen as a luxury. Robotics supports by accelerating the order and customization specificity. Personalized packaging, customized shipments, unique requests, etc… automated systems can accommodate these scenarios much more efficiently when compared to manual processing. This equates to the better customer experience and higher brand loyalty.

Robotics as a Competitive Edge

Companies that incorporate robotics into supply chain operations have an undeniable advantage. They claim faster fulfillment, better accuracy, and greener credentials to stand out in crowded markets. A robotics company in Dubai that bring automation in-house, the ones that don’t add robotics to the mix will increasingly find themselves on the wrong side of the divide. The early adopters are not just cocking a snook at their rivals, they’re starting to gain strategic advantages.

Preparing the workforce for tomorrow

The rise of robotics in the supply chain requires a new approach to workforce development. Instead of taking jobs away, robotics makes it about reskilling and upskilling workers. Workers need to learn how to work, maintain, and cooperate with robotics. This shift in responsibilities opens the door to more valuable jobs and helps ensure that workers are future-fit in an ever more automated economy.

The Road Ahead

The future of robotics automation in supply chain management is ever evolving. In the future, supply chains will only get faster, smarter and more adaptive as technology progresses. Businesses that adapt to this change will gain a competitive advantage by bringing more reliability and efficiency to consumers. Robots aren’t going to do away with human creativity, but rather amplify it to usher in a new era where innovation takes the driver seat in transporting goods around the world.

Discover the Power of Robotics Automation in Supply Chain

Ready to take your business to the next level? Embrace Robotics Automation in Supply Chain to improve efficiency, reduce costs, and deliver with unmatched accuracy. At IQ Robotics, we provide smart solutions that keep your operations running seamlessly from warehouse to last-mile delivery. Stay updated with the latest innovations and success stories by following us on Facebook. Join the conversation and explore how automation can future-proof your supply chain today!

FAQs

1. In which ways are robotics currently available for the supply chain?

Robots are used for picking, packing, sorting and transporting items, and even tracking inventory. They collaborate with humans to move more quickly, accurately and efficiently through warehouses and distribution centers.

3. How does AI factor into supply chain robotics?

AI helps robotics to improve on predictive analysis, adaptative decision and real-time optimization. This allows robots to not just complete tasks, but also predict demand, identify disruptions and enhance the resilience of the supply chain.

4. Are BotXO’s robotics solutions reasonably priced for SMEs?

Yes. Although early adoption was mostly limited to big companies, the price of robotics technology is coming down. Scalable modular solutions are now available, enabling smaller businesses to take advantage of automation for greater efficiency.

5. What will robotics mean for worldwide logistics?

It will be day and night in publishing, with robotics applied in shipping ports, warehouses and even customs. More rapid processing, less human error and live tracking will mean more efficient – and more resilient – global supply chains.

6. What is Robotics Automation in Supply Chain?

Robotics Automation in Supply Chain refers to using advanced robots and AI-powered systems to handle tasks like picking, packing, sorting, and delivery. It helps businesses reduce manual errors, increase speed, and achieve 24/7 operational efficiency.