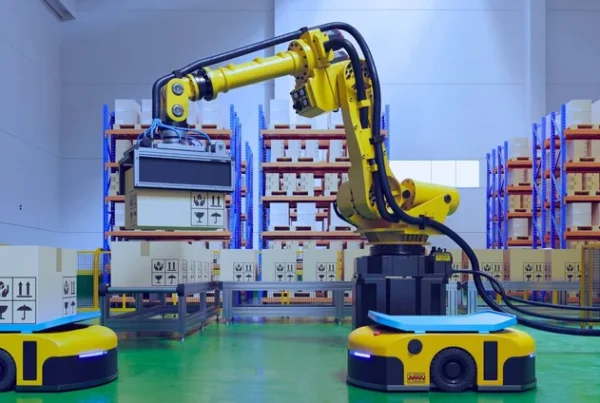

The UAE is emerging as one of the world’s leaders in innovation and smart technology. As digital transformation reshapes every industry, warehouses across the nation are rapidly adopting automation at an unprecedented pace. At the heart of this shift, robotics warehousing automation is revolutionizing goods processing, sorting, and delivery—tasks that were once highly labor-intensive.

Rising Demand for Efficient Warehousing

The significant expansion of the e-commerce and retail sector in the UAE has led to warehousing operations being under increasing amounts of pressure to deliver ever more rapidly and effectively. High-volume sorting: Manual processes on the ground can have difficulty keeping pace with efficient high-sorting volumes, which tends to spike during peak seasons. Robotics sortation systems offer a solution for this problem by introducing speed, consistency, and real-time control into warehouse operations.

What Are Robotics Sortation Systems?

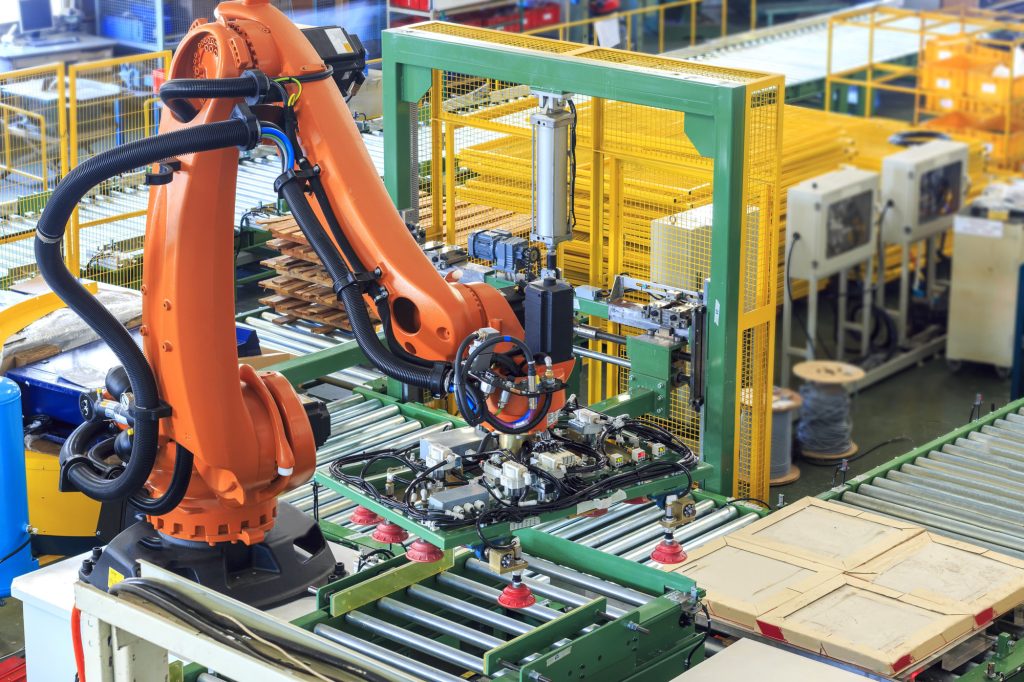

The robotics sortation systems execute sorting work through intelligent robots that can recognize, pick up, and move items based on specified rules. Many of these systems rely on barcode scanning, computer vision, and AI software. Robots could traverse the warehouse and get down to the warehouse floor picking products of different sizes, in different areas or delivery zone safely all without human intervention and then place them where they belong. This largely reduced errors and helped in making a faster workflow.

Benefits for UAE Warehouses

Those benefits are already making a big impact in the UAE with robotic sortation deployed at warehouses. It increases the speed, make them safer, and more cost-effective. Monotonous sorting can be carried out by the robots themselves, so human workers would only have to focus on tasks that need decision-making. These systems also reduce labor costs, decrease injuries and increase accuracy. The UAE, already on a mission to lead the new tech economy and working hard on its digital excellence, is grades above in running such services hand-in-hand with its vision towards smart economy.

Scalability and Flexibility in Action

Flexibility is another key advantage of robotic sortation. Since these systems are scalable it is easy to scale the system up as warehouse needs grow. That means you can add new robots, upgrade the software or change sorting logic without changing everything in one go. This is a game changer for the UAE businesses who have some local and global shipments to handle.

Key Industries Benefiting

Robotic sortation systems are used across different sectors, including retail, e-commerce logistics, and healthcare in the UAE. The gold standard for automated fulfillment has been set by companies such as Amazon and Noon. Following suit, local logistics providers have been keeping pace by lining up big investments in robotics solutions. Smaller systems are now used even by typical mid-sized warehouses to remain competitive, with some exploring advanced technologies like IQ robotics to enhance efficiency.

Challenges and the Road Ahead

The challenges of robotics warehousing automation system come despite obvious benefits. The initial cost is usually very high and a good team of technical members are needed to be there for manage the systems. Fortunately, the UAE is building up its investment in AI, robotics and 5G infrastructure so these issues are being tackled with. Support from the government and private investment are helping create an ecosystem that automation can flourish in.

Conclusion

Not a future concept anymore but the robotics sortation system in UAE is now changing warehouses. This power is speed, precision and intelligence that supply chains on a move need. Given the demand from businesses for more intelligent, faster and larger scale systems of operation, automation powered by – robots will be front and center. The unrelenting march of innovation will continue to make sure the UAE warehouses remain some of the most sophisticated in the world.

FAQs

1. What is a Robotics Sortation System

A robotics sortation system (robotic sorting device) can be programmed to identify, pick, move and put specific items in place in the warehouse. In the warehousing these robots scan products and uses AI technology to accurately places the product based on destination, size or type.

2. So what is driving UAE warehouses to adopt robotic automation?

UAE warehouses require faster and more accurate sorting for growing e-commerce demand. To this end, robotics eliminates the need for manual intervention that in turn reduces many errors and helps increase processing speed at significantly lower labor cost while firmly pushing the UAE towards realising its vision of being a global smart logistics hub.

3. What makes robotic sortation systems great for your same day delivery?

They help to speed up sorting tasks, decrease the risks of human error, and operate 24/7. Thousands of items per hour can be sorted by robots, providing human workers the opportunity to concentrate on decision-making or quality control roles.

4. what types of warehouses in the UAE stand to benefit most from robotics.

The success are e-commerce, logistics, retail, grocery and pharmaceutical warehouses. Be it consumer products, or medical supplies — robotic systems improve accuracy, security and quickens the supply chain too in any domain.

5. Is Scalability Difficult for Small Businesses to Achieve with Robotics Sortation Systems?

Yes. Today, robotic solutions are modular and they scale. A number of UAE-based start-ups and mid-sized warehouses have installed compact systems that can be accommodated within their budget and space without the need for a full facility redesign.

Stay Connected!

Want to see how automation is transforming real-world warehouses? Follow us on Instagram for industry insights, behind-the-scenes innovations, and expert tips to keep your operations running smoothly. Join the conversation and stay updated on the future of smart warehousing!