Introduction

As automation takes the world by storm, no industry is being transformed as rapidly as warehousing. As warehouse robotics assumes roles once held by human hands, such as picking, packing, visual inventory management, and transportation, the question arises: What does the future hold for human labour in an automated warehousing? The answer is complicated and multifaceted, involving economics, technology, ethics, and workforce development. This blog post examines the trade-off between robotics and human labor in warehousing, its implications for the future of jobs, and how both businesses and workers can adapt to the anticipated changes.

Fueling the Growth: Warehouse Automation

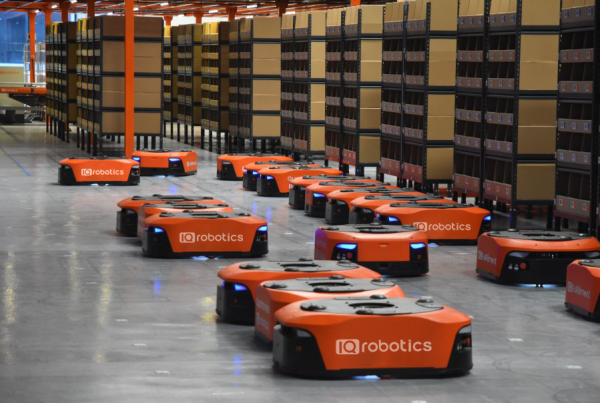

Warehousing automation is not a new concept, but the scale and sophistication of the technologies today are. What started as conveyor belts and barcode scanners has evolved into fleets of autonomous mobile robots, AI-powered sorting systems, and predictive inventory software. These systems aren’t simply supplementing human workers; they are starting to supplant some tasks entirely. In an environment where high delivery speed and tight logistics are crucial for competitors, automation is not only imperative but also necessary.

Tasks Robots Excel At

The robotics systems making their way into modern warehouses are particularly adept at performing repetitive, rule-based tasks. These tasks include selecting products from shelves, moving goods across warehouse floors, scanning inventory, and even packaging. Thanks to sensors, cameras, and machine learning algorithms, these robots can operate with remarkable consistency and precision. These innovations are especially advantageous for high-volume fulfillment centers that experience demand spikes during peak seasons.

Where Humans Still Have an Advantage

Robots have advantages, but they also have limitations. Jobs that require cognitive flexibility, problems that need real-time solutions, and decisions that depend on nuance remain squarely within the realm of human dominion.

Economic Incentives and Labour Trends

The cost-effectiveness, being one of the primary factors driving the adoption of automated warehousing, labour shortages, escalating wages, and the high cost of workplace injuries, makes robots an increasingly financially attractive solution. Wait time can also hurt your bottom line. Still, in several cases, operation line number nine can be automated to increase throughput without introducing a wealth of errors into the system.

The Effects on the Human Labour Force

Automation presents both a threat and an opportunity for the human workforce. There is a high risk of displacement for jobs that are repetitive and manual. At the same time, automation is creating new jobs, such as robots’ maintenance, data analysis, systems engineering, and automation supervision. These are generally higher-skilled jobs, offering better wages and more promising career prospects. This is why so many companies and governments around the world are recognizing the need for workforce development and investing in programs to upskill existing employees and train new ones to fill the skills gap.

Emerging Norm: Human-Robot Collaboration

Instead of complete replacements, the future, in all likelihood, is one in which people and robots work together. This model, referred to as “cobotics,” involves humans and robots working together, with each doing what they do best. One task can be carried out by a human and another by a robot; a human might oversee quality control, for instance, while a robot handles tasks such as lifting, carrying, and moving objects from one place to another. This symbiotic relationship can lead to increased productivity and enhanced workplace safety. Effective cobotic systems rely on natural interfaces and secure interaction protocols to foster a harmonious relationship between humans and robots.

Ethics and Wellbeing in the Workplace.

However, as robotics becomes increasingly widespread, ethical questions also arise. And should companies focus on profit rather than people? What responsibilities, if any, do employers have to displaced workers? How can we ensure equitable access to retraining programs? Automation Strategies need to be based on transparency, equity, and social responsibility. These involve employee negotiation in the decision-making process, clear communication regarding the changes in place, and guidance during transitions. In the long term, automation should augment rather than undermine human capabilities.

Adoption and Impact Across Regions

Automation does not affect all regions equally. For warehouse automation in UAE, countries with high labour costs typically have a significant economic incentive for automation. By contrast, in areas with plentiful and cheap labour, the economics of automation may take longer to add up. Local infrastructure, government policies, and educational systems also influence the patterns of automation.

Ready for a Plus Flipped Future

Automation shouldn’t be resisted; however, its course should be carefully plotted. The focus is on preparing businesses for a blended workforce that combines humans and machines. Taking this step means that organizations will need to rethink job roles, redesign workflows, and nurture a culture of continual learning. Logistics and supply chain management leaders must continue to iterate and innovate, but with empathy and consideration for the needs of their stakeholders. By leveraging automation to enhance human productivity, rather than diminish it, companies can achieve long-term growth while upholding social responsibility.

The Evolution of Warehouse Ecosystems through Innovation

Technological innovation is being rolled out at an incredible rate, and while the current system may be comfortable for individuals, this approach is disrupting entire ecosystems in warehouses. Modern warehouses are becoming increasingly intelligent with the rise of AI, machine vision, IoT, and cloud computing. Real-time data analysis now informs operational decisions, from when to restock shelves to which routes to follow.

The Threat from Startups and Tech Disruptors

While big corporations spearhead the warehouse automation effort, startups and tech disruptors are helping to democratize innovation. These options typically have lower initial costs and are easy to integrate, allowing organizations of all sizes to implement automation. With the evolving competitive landscape, these agile innovators are blurring the lines, contributing new models for human-robot collaboration in logistics.

Automation for the Environment – Environmental Implications of Automation

Automation affects more than just productivity and employment; it also has significant environmental implications. Today, robots can also help achieve sustainability goals by optimizing energy consumption, reducing waste, and minimizing unnecessary packaging. Conversely, concerns exist about the environmental impact of electronic waste and carbon emissions associated with the production and disposal of robotic parts. From creating energy-efficient robotics to utilizing recyclable materials, companies adopting warehouse robotics need to look beyond the equipment they own, towards solutions that facilitate the life-cycle sustainability of their technology choices, which align well with sustainability goals set globally.

Education and Workforce Readiness

As warehousing continues to evolve, education and workforce development must do so alongside it. Now, traditional job training programs are required more than ever to incorporate modules on robotics, data analysis, and digital tools. Technical institutes, universities, and a growing number of corporate training centers are beginning to offer specialized courses that prepare workers for hybrid roles in automated environments. Lifelong learning is no longer a luxury but a requirement. To prevent workers from being left behind in the transition to a digital economy, governments and private sector leaders must invest in new training pathways that are both accessible and affordable.

A Long-Term Vision: Humans in Their Role as Strategic Leaders

In summary, the most valuable roles in automated warehousing will be those that are strategic, creative, or leadership-oriented. Real humans will still be needed to manage change, interpret complex data, innovate logistics solutions, and lead cross-functional teams. Robots may do the heavy lifting, but people will still be the builders of progress. We are preparing the future workforce to embrace innovation, adapt, and work with machines as an ally, thereby strengthening our workforce in a rapidly changing landscape. This long-term vision underscores the importance of human intelligence at the heart of the next generation of logistics.

Conclusion: Human work, redefined

The robots in warehouses represent a profound transformation of the work. And while job displacement is indeed a significant threat, we don’t live in a zero-sum world where people and machines compete against each other. Instead, it is an opportunity to reimagine work, upskill talent, and create more innovative, safer, and more efficient operations.

As the world of warehousing continues to evolve, staying informed and adaptable is key to thriving in this era of automation. If you’re passionate about the future of work, technology, and innovation, or if you’d like to connect and exchange ideas, feel free to connect with me on LinkedIn.

Let’s shape the future together!