Introduction

Warehouse automation is proving to be a revolutionary force in logistics and supply chain management. With businesses pressured to maximize operations, streamline efficiency, and reduce costs, the move toward automated warehouses evolves as a strategic solution. Implementing advanced technologies, such as robotics, artificial intelligence (AI), and automated guided vehicles (AGVS), can drive operational efficiency and enable businesses for long-term growth. In this blog, we take a look at the benefits of warehouse automation ROI that lead to cost savings and scalability, ultimately building a case for automation.

Investing in Warehouse Automation – The ROI

One of the top considerations for businesses looking to invest in automation is return on investment (ROI). Implementing warehouse automation can be quite expensive initially due to the significant investment required in technology, infrastructure, and training. However, the initial costs are outweighed in the long run by the benefits. Additionally, businesses can leverage data analytics paired with an automated warehouse picking system to make data-driven decisions that impact warehouse layouts, inventory management, and order fulfillment. Real-time data enables companies to optimize their operations, reducing waste and aligning resource allocation more accurately, resulting in even higher ROI.

Efficiency Gains Through Automation

The initial investment in automation technology may be substantial, but it yields considerable savings over the long term. Labour costs frequently represent the most significant expense for forehabses, and automation offers a systematic way to reduce these costs. With the use of robots, conveyors, and AGVS, warehouses can reduce the number of human workers needed to perform repetitive, low-skill tasks. Automation also reduces downtime caused by worker breaks, absenteeism, and turnover, creating additional savings. Another major cost-saving advantage of warehouse automation is the decrease in mistakes. Human workers often make errors, particularly when performing repetitive tasks under high pressure.

Scalability: The ability to grow as your business expands

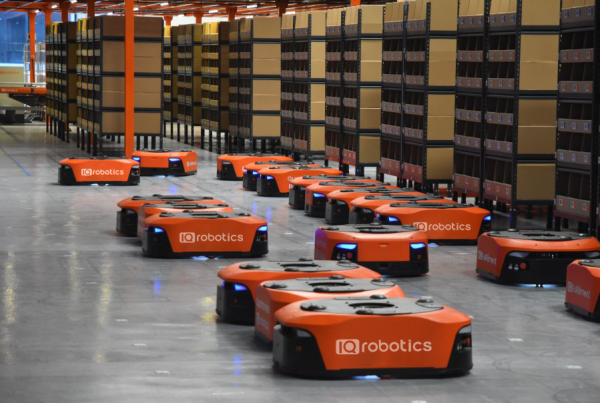

Another reason warehouse automation is appealing to businesses is its scalability. Operational needs expand along with companies. When demand increases, these manual systems may struggle to cope properly, inevitably resulting in bottlenecks, inefficiencies, and higher labour costs. Automation offers a scalable solution that is easy to implement, enabling businesses to meet increasing demands. You can scale automated systems for higher volumes without a massive overhaul. We can add additional robots or automated vehicles as ordered volumes increase, which can help businesses scale rapidly and cost-effectively. This flexibility means that automation is well-suited for companies with cyclic demand patterns or rapid scale-up expectations.

Now, let’s get into the benefits of automated solutions.

Space is a very limited commodity in warehouses, so any automation translates to the most efficient utilization of the space at hand. Automated systems, such as narrow-aisle robots and vertical lift modules, enable businesses to maximize storage capacity by utilizing the warehouse’s vertical space and minimizing the use of wide aisles. By keeping everything you need within reach, you’ll need fewer rooms to store items and may not require extra space in your home, which can be costly. Alternatively, you may not need to rent a storage space at another location.

Warehouse Automation: Your Competitive Advantage

Implementing warehouse automation provides not only significant internal benefits but also results in a competitive advantage for companies. In a competitive, consumer-centric landscape, businesses are being challenged to deliver faster, more accurate, and more affordable products. Automated systems are a solution to those customer demands. Automation enables orders to be processed more quickly, resulting in shorter lead times and increased delivery speeds. It further improves inventory visibility, allowing the companies to monitor stock levels more efficiently and accurately forecast demand. This results in increased customer satisfaction, improved retention rates, and a more competitive edge in the market.

Lowered Implementation Complexity

As businesses scale, complexity in warehouse operations also begins to emerge. Managing inventory, ensuring accurate orders, and coordinating multiple tasks throughout large areas can be difficult. Automated systems simplify this complex web by centralizing control and providing real-time data for streamlined operations. Tasks such as inventory management, picking, packing, and shipping can now be streamlined into a seamless workflow with automation. This thereby minimizes intervention and eliminates errors caused by complex manual operations. This enables businesses to run their operations more smoothly and helps reduce operational overheads, improving efficiency.

Integration with Other Technologies

Therefore, warehouse automation is not a standalone solution and can be integrated with other technologies to significantly augment supply chain operational efficiencies. For example, WMS can be integrated with inventory management, forecasting, and order tracking, resulting in a streamlined flow of data throughout the supply chain. Such integration enables businesses to track their performance in real-time, detect inefficiencies, and make data-driven decisions. Integrating automation with Iot, AI, and other technologies can result in warehouses becoming smarter, which allows companies to predict maintenance needs better, track asset performance, build predictive maintenance schedules, and forecast demand more accurately.

Better Labour Management

Automation may go on to decrease the number of workers required to handle repetitive tasks, while at the same time allowing the business to control of implement the organization of their human capital. By assigning tedious duties to machines, humans can spend their time on higher-value work that requires creativity, critical thinking, or face-to-face interaction with customers, not so much from the standpoint of jobs lost, but from the perspective of employment gained — getting people out of monotonous or physically demanding work and into stimulating environment. And with many labour-intensive functions automated, businesses are free to scale up or down without constantly hiring or training additional personnel.

Environmental Benefits

In addition to savings and efficiency, warehouse automation can also contribute to environmental sustainability. Layouts are optimized to maximize floor area within warehouses, allowing for more packages to be housed within the same footprint, which improves transport efficiency and ultimately lowers the carbon footprint of warehouse operations.

For example, automated guided vehicles (AGVS) and robots are usually more energy-efficient than traditional forklifts and machinery. Automation also enhances inventory control, minimizing the potential for unnecessary production and waste. VPS helps reduce waste and minimize the environmental footprint of overproduction or unsold stock by better managing stock levels and ensuring that products are stored according to best practices. The use of energy-efficient systems in automated warehouses also directly contributes to a company’s sustainability ambitions.

Long-Term Strategic Growth

Building a warehouse automation system comes with direct benefits that contribute to future growth. As e-commerce evolves and consumer expectations rise, businesses must maintain their agility to support growing volumes and increasing complexity. With automation, it is possible to scale up quickly by eliminating manual processes in response to changing market needs, without the significant costs associated with infrastructure. This enables warehouse automation to be a key driver for businesses looking to expand, penetrate new verticals, or service increased consumer demand without compromising on efficiency or profit margins.

Conclusion

Warehouse automation is not merely a fad; it provides ROI, along with significant cost savings, greater scalability, and operational efficiency, making it a long-term investment. Automation is the next frontier in productivity, and as companies struggle to stay competitive in our rapidly digitalizing and fast-moving economy, automation promises to intensify the competition by improving output while holding down costs and enhancing customer service. This makes warehouse automation an excellent long-term solution for any business seeking to streamline its operations and increase competitiveness in its industry, allowing companies to scale their operations and optimize space and accuracy.

If you found this article insightful and want to stay updated with the latest trends in warehouse automation, logistics, and supply chain innovation, follow us on Facebook. Join our community to explore expert tips, industry news, and practical solutions that can transform your operations and drive long-term business success.