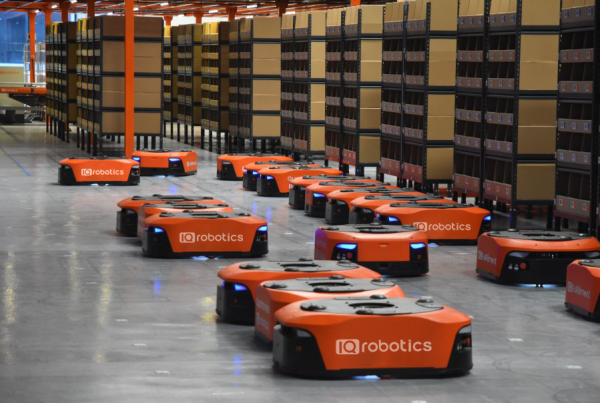

The transformation of the logistics industry through the power of technology is an issue most professionals in the industry are grappling with. Robotic sortation systems are making a central contribution. They assist warehouses in processing thousands of parcels by the hour, with unequaled accuracy and speed.

Modern Warehousing: The Era of Robotic Sortation Systems

Overview

Traditional sorters start to run short as businesses grow in both size and volume. Robot sorting offers precision, speed and the ability to adapt in real time for today’s warehouse operations.

Key Offerings

- Features quick and precise item sorting via AI and advanced sensors.

- Integrates with any Warehouse Management Systems (WMS).

- Providess flexible layout according to the size or category of products.

- Guarantees less labor cost and as less human made mistake.

Why It Stands Out

GCC warehouses instantly transform their operations for order fulfilment and dispatch with the expertise of robotic sortation systems working in tandem at high speeds and with an IQ to match.

How It Makes Order Fulfillment More Efficient

Overview

Speedy processing is not the only benefit of sortation robotic automation. That is to make sure everything moves where it should with zero error.

Key Offerings

- Employs smart algorithms to identify and route parcels in real time.

- Optimize conveyor and shuttle movements for continuous operation.

- Improves productivity, minimizing downtime in service and maintenance.

- Enables real-time visibility for warehouse managers to data.

Why It Stands Out

Robotic sortation also enables logistics operators to fulfill or deliver within tight time frames which are common across UAE hubs such as JAFZA and Dubai South.

Tailoring to GCC Disruptor Services for the future of E-commerce Market

Overview

The e-commerce industry in the UAE requires quicker delivery and utmost precision. Robotic sortation systems allows fulfillment centers to scale to accommodate seasonal peaks without interruption.

Key Offerings

- Manages High SKU Variations popular in online retail.

- Manages order spikes during high-traffic events such as Dubai Shopping Festival.

- Scales up and down the size of any warehouse configuration with modular designs.

- Synchronizes with local distribution networks for seamless last-mile delivery.

Why It Stands Out

This flexibility aligns with the UAEʼs ambition to be a global logistics hub enabled by state-of-the-art automation.

Smarter Data, Better Decisions

Valuable data are produced at all levels in robotic sortation systems. Managers have information in hand for order pattern analysis, performance traceability and demand prediction. Companies can now eliminate bottlenecks and make decisions in real time. This data-enabled approach offers stability and continuous customer satisfaction in high-paced GCC markets.

Operationalizing for Sustainability and Scale

Robotic sortation not only delivers performance, however, it carries with it green benefits as well. It uses less power, involves fewer manual steps, and cuts down on the waste of dispatching misrouted packages. As UAE logistics companies embrace more sustainable business models, automation remains a crucial part of the solution to meeting national sustainability targets.

Seamless Integration with Existing Infrastructure

Today’s robotic sortation systems are engineered to be modular and seamless within existing warehouse footprints. With standard conveyor lines or semi automated flows, they directly link perfectly without any down time in between. With WMS and ERP integration, it enables companies to have a 360-view of items from receiving to shipping. Such a seamless connection allows upgrades to improve performance without interfering with ongoing functionality.

Enhancing Workforce Productivity

Automation does not take away jobs. It makes people more effective. In UAE warehouses, the robotic sortation solutions process routine sorting so human staff members can focus more on managing quality control, packaging and servicing customers. This change of position lowers tiredness, enhances a sense of safety, and increases job satisfaction. Combining human capabilities with robotic precision drives up productivity levels at fulfillment centers, without raising stress levels among workers.

Cost Efficiency Through Long-Term ROI

While the capital expenditure in robotic sortation at first may appear substantial, the ROI is transparent and calculable. With more efficient labor, less error and faster processing there are huge operational savings. Return on investment are also fast, in the high density areas such as Dubai South and Abu Dhabi Industrial City since it aids to increase the throughput and reduce downtime for businesses. With time, such automation is not just a performance aid; it’s a financial windfall.

Realizing the GCC’s Vision for Smart Logistics

The logistics industry in the GCC is turning to innovation to remain competitive on a global platform. Robotic automation sorting systems meet regional ambitions towards digitalization and smart warehousing. UAE Governments are driving technology-enabled logistics parks and free zones which is raising the industry bar. Through the integration of robotic sortation, companies are actively advancing the region’s push for more efficient, sustainable and AI-driven supply chains.

The Road Ahead for Fulfillment in the UAE

Sortation systems with robotics are no longer nice-to-have; they’re a necessity for companies that compete in the regional and global markets. Thanks to cutting-edge automation and AI integration, UAE warehouses will now be capable of same-day fulfillment and limitless growth.

Sign up at IQ Robotics to get a customized consultation or visit us on LinkedIn to get to know more.

FAQs

1. To what extent can robot sortation systems increase warehouse productivity?

They increase efficiency, accuracy and productivity while minimizing manual handling and human errors.

2. Do those solutions interface with and connect back to current WMS systems?

and yes the Robotic sortation can easily interface with any Warehouse Management Systems (WMS) for seamless data exchange.

3. Are robot pick and place systems suitable for GCC region?

Systems are engineered for specific regional climates so that they perform efficiently even in high-temperature weather.

4. In which sectors does the robotic sortation flourish in the UAE?

The sectors that gain the most are e-commerce, retail, logistics/3PL.

5. Why Your Company Name for robotic sortation?

IQRobotics is one of the best providers in the UAE that can provide you with tailor-made automation solutions tailored for GCC-scale logistics operations.