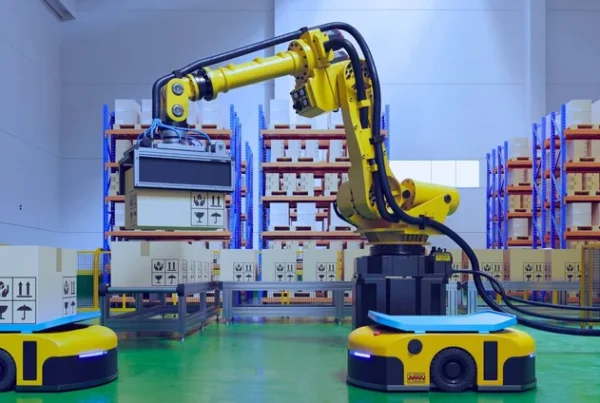

The UAE’s logistics sector is rapidly changing. They have help from robotics and automation. Warehouses are more than storage these days. They are machine-linked smart hubs for moving goods. Robots complete the task of picking, packing and sorting items. This accelerates progress and minimizes human errors. UAE Warehousing is being transformed by automation daily.

Automation for Increased Efficiency

Robots, of course, are more efficient than people. They perform the mundane without getting bored. This leads to more being processed in a shorter period. Automated systems also minimize errors. Fewer mistakes translate to happier clients and less waste. In the hustle and bustle of the UAE’s markets, speed and precision are key. For companies with tight deadlines, automation makes things achievable.

Spending Less, Using Resources Better

On the surface, robotics can be expensive. But over the long term, they save money. Robots reduce labour costs and increase productivity. They decrease on-the-job injuries by performing dangerous tasks. And automated warehouses make better use of space, as well. Which is to say, companies can store more stuff in less space. You quickly save time and space.

Safety and Reliability Improvements

Warehouses are dangerous places to toil. Accidents can occur when heavy lifting and moving take place. Robots replace these risky jobs. They adhere to programmed routes and safety protocols. This lowers the risk of injuries. Automation can be used to play evenly. Operating capabilities that can be trusted, to reinforce the trust with customers or partners.

Enabling UAE’s Thriving E-commerce Industry

The e-commerce market in the UAE is exploding. Larger warehouses are necessary as online orders rise. And robotics is here to fulfill this increasing demand. Large capacity is processed automatically without lag. This allows fast deliveries to customers. As e-commerce expands, robotics will become even more critical.

Smart Technology Partnering

Robots don’t work alone. They do integrate with other intelligent systems. Sensors, artificial intelligence and data analytics determine what they do. This is what makes warehouses more innovative and more flexible. Companies can see how much inventory they have on hand in real time. They are highly adaptive to changes. This integration of tech is revolutionizing logistics in the UAE.

Minimising Human Error in the Warehouse

Warehouse workers are expensive to replace, and human errors in warehouses are costly to correct. Misidentification in the picking or packing process results in incorrect shipments. They can be eliminated by the introduction of robotics automation. Robots don’t get sidetracked or thrown off by instructions. This results in more accurate orders and happier customers. The fewer mistakes, the more money is saved in time and cost by businesses. The Emirati logistics sector is a significant beneficiary of this dependability.

Inventory Management That Moves Faster

Good inventory is the key to a successful business. The old ways tend to be slow and inefficient. Counting and tracking stock becomes faster with robotics automation. Robots constantly update data through scanners and sensors. The real-time information is, of course, valid for managers who can then make intelligent decisions. The faster you are at taking inventory, the less lag and out-of-stocks. This is a game-changer for UAE warehouses when it comes to inventory.

Enhancing Scalability for Expanding Enterprises

The bigger businesses become, the more they have to deal with logistics. The manual doesn’t scale. The manual is expensive and complicated. Robots help to simplify and speed up scalability. At the same time, automated systems can intake more and do so without the need for additional staff. Firms can add as many robots as they want. This agility is in the interest of the UAE’s fast-emerging businesses. With the rise of robotics, warehouses are building up, not out.

Lowering Environmental Impact

Using robotics for warehousing automation can be an energy saver. Robots don’t just optimize their routes to save power. Automated systems cut down on waste by making fewer mistakes. By using space efficiently, you have less need for massive warehouses. Specific robot models use clean energy or are battery-rechargeable. This is in line with the UAE’s green targets and environmental sustainability objectives. Logistics in cleaning means a healthier environment for all.

Job Creation

Robots are feared to displace workers. But robotics also generates new jobs. Systems need individuals to oversee them and keep them running. Skilled workers oversee robots and solve problems. When they were first introduced, automation allowed workers to stop doing their monotonous work. They can concentrate on more value-added work, such as planning and innovation. UAE Job market sees collaborative work between robotics and humans.

Enhancing Customer Experience

Fast and precise delivery is beneficial to the customer’s content. Orders are processed swiftly with robotics automation. Customers get their goods delivered. Fewer errors also ensure that customers receive their orders as placed. This engenders trust in e-commerce and retail brands. In the UAE’s cutthroat environment, good service comes first. Automation enables companies to keep their customers happy and loyal.

Reducing Operational Downtime

In the case of manual warehouse operations, processing can also be delayed because of human fatigue or errors. Robots don’t take breaks and work around the clock. They hold firm all day long. This means less downtime and more uptime. Automated processes help to raise the warehouse productivity overall. It’s a regular cadence that helps to sustain UAE logistics. Less downtime leads to speedier deliveries and larger profits.

Facets of Multi-Channel Fulfilment

Many companies now sell through multiple channels. Warehouses need to fulfill orders from stores, websites and marketplaces. Robo-systems handle such composite orders effectively. They pack and sort items for various channels without any confusion. This makes fulfillment easy across sales channels. Multichannel support is the way for your UAE business to remain competitive and expand.

Thereby, the Creative Development Encouraged

Automated lets companies innovate their logistics. Robotics allows for new technology and more intelligent systems. Robots are purchased alongside investments in AI, machine learning, and data analytics by businesses. It allows for greater decision-making and planning. Innovation is what fuels growth and what separates companies from, say, their competitors. In the UAE, novelty is vital for marketability.

Overcoming Labour Shortages

Labour shortages are a problem for the UAE in specific sectors. Warehousing is no exception. Robotics has been an effort to bridge this divide by taking over such repetitive work. This minimizes the requirement for a large number of manual laborers. It also enables human workers to work on more complicated operations. 3-D printing is a way to boost productivity and bridge the labour gap. Robotics is another, too. It helps the UAE transport industry run like clockwork.

Improving Order Accuracy

The use of robotics warehouse automation leads to a significant increase in order accuracy. Robots pick items exactly as per the order. This cuts down on mistakes, like incorrect items or missing items, for instance. Orders that are correct result in fewer returns and fewer complaints. Customers know what to expect every time. This enhances trust and satisfaction. In the UAE market, correctness can lead to a reputation.

Faster Returns Processing

Returns are a significant headache for logistics. Return processing is accelerated through robotics automation. Robots quickly scan and sort returned items. It’s faster for stocking or dumping, too. Speedier returns mean fewer products sitting in warehouses. It also enhances customer service for buyers. Quick returns are in demand in the UAE to accommodate e-commerce growth.

Enhancing Warehouse Security

Warehouses contain good property. There’s an additional layer of security with robotics automation. Robots and sensors run warehouse operations 24 hours a day, seven days a week. They spot intrusions or suspicious activity. Managers are immediately notified about the risks from automated systems. This enables the safeguarding of inventory against theft or damage. Safe warehouses inspire confidence in clients and partners.

Predictive Maintenance at Your Service

Robots need lots of tinkering to be effective. Predictive maintenance features are built into all automation systems. The tools are designed to monitor the robot’s health as it works. They forecast when a robot is going to break or an engine will require maintenance. This reduces the risk of surprise breakdowns and downtime. Warehouses are kept running smoothly with predictive maintenance. It reduces repair expenses and extends the life of the robot.

Promoting the Policies of Sustainable Development

The UAE has the environment high on the agenda of many of the country’s businesses. Robotics warehousing contributes to these objectives. Warehouse automation in the UAE minimizes waste and energy use. This maximizes any available space and minimizes the environmental impact. A few warehouses use solar to power robots. Eco-friendly customers are drawn to sustainable products. Robotics also enables companies to achieve green objectives and enhance their image.

Removing Redundancy from the Supply Chain

Robotics automation is bringing a sense of order to the entire supply chain. Robots speed goods from suppliers to warehouses. They minimize downtime due to manual operation. This allows inventory to be on hand more quickly for orders. Efficient supply chains lower costs and save on delivery times. Efficiency is key in the UAE, and this is a huge advantage. More control and transparency in logistics with robotics.

Enabling Data-Driven Decisions

Robotic systems are data-driven. This is data that managers can use to understand how well this warehouse is performing. They can see bottlenecks coming or forecast changes in demand. It makes sense to have data-driven decisions, for this brings efficiency and reduces the cost. Robotics transforms warehouses into intelligent and nimble spaces. The latter insight, in particular, gives UAE companies a competitive advantage. More innovative logistics are driven by technology every day.

Creating resilience against disruption

Global events can neatly disrupt supply chains. Robotics Automation Makes Warehouses More Robust. Robots keep things humming, even with fewer workers. Robotic systems quickly readjust to changes in their environment. Warehouses use the flexibility to deal with surprises. For the UAE, resilience, on the other hand, is to provide continuous service during crises. To prepare for potential future disruptions, robotics buttresses logistics.

The future of the robotics warehouse

The future of logistics in the UAE is bright. Robotics and automation will continue to develop. More businesses will adopt them. We can anticipate warehouses that are yet faster, yet safer, yet cheaper. This will further enhance the UAE’s standing as a global logistics centre. Robotics is not a fad; robotics is the future of the warehouse.

Want more updates on how robotics and automation transform the UAE’s logistics landscape? Follow us on Facebook for the latest insights, trends, and innovations driving the future of smart warehousing. Join the conversation and stay ahead in the age of intelligent logistics.