Across the UAE, as more businesses adopt warehouse picking automation, fulfilling orders quickly and at scale has become essential. In a hub of smart logistics innovation like Dubai, IQ Robotics is transforming warehouse automation UAE, redefining how products are picked, packed, and shipped. Their advanced systems boost productivity and efficiency across the entire supply chain.

Reasons for Automating Warehouse Picking

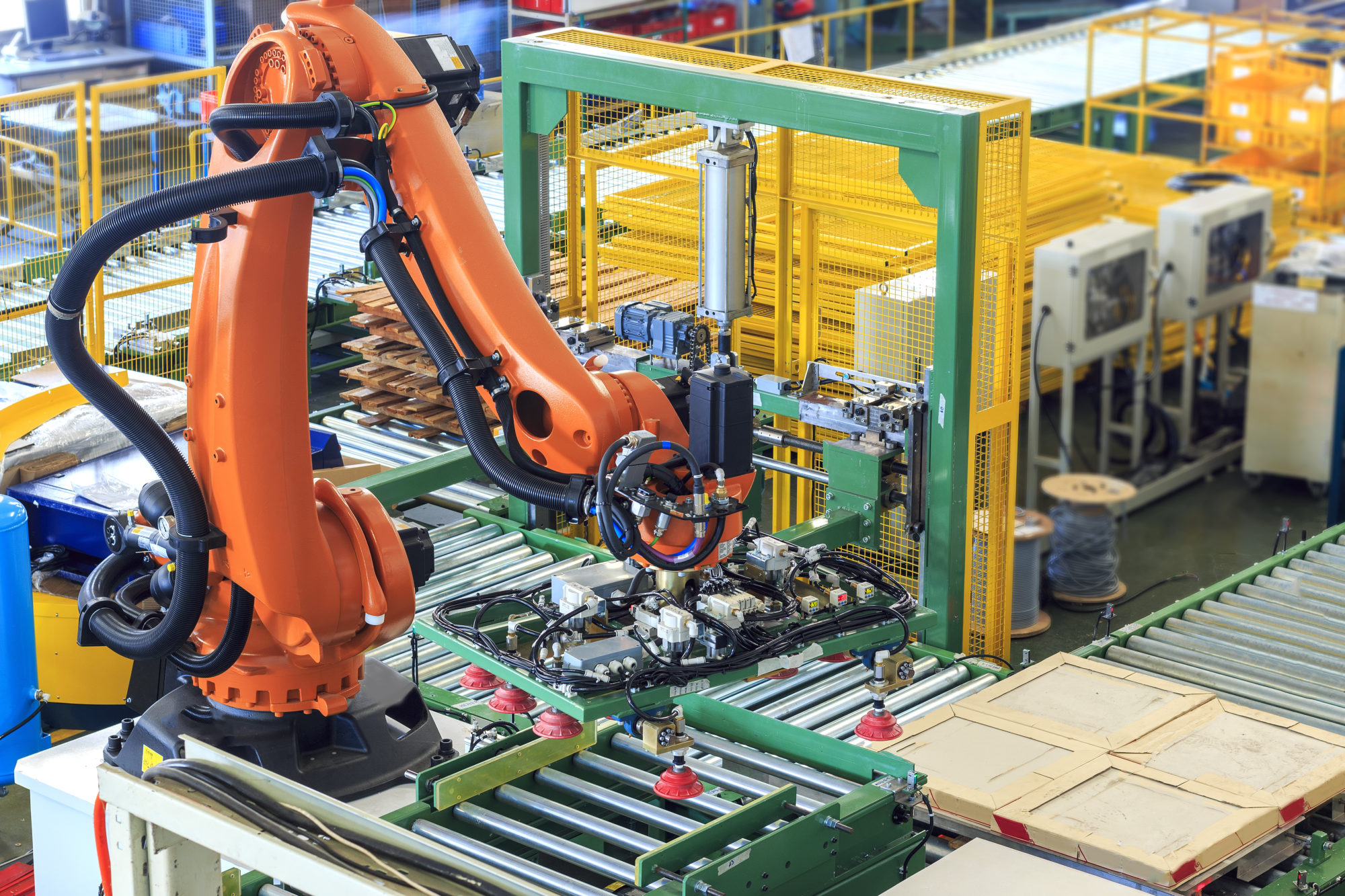

In any warehouse, one of the most labor-intensive tasks is order picking. Especially in the domains of e-commerce, retail, and pharmacy, it is a time-bounded process that requires speed, precision, and continuous synchronization. Manual picking frequently results in delays, errors, and high labor costs. Warehouse automation UAE solves this issue by taking human error out of the equation, leveraging smart robots, sensors, and AI systems to handle picking tasks more quickly and accurately.

The Role of IQ Robotics in Dubai

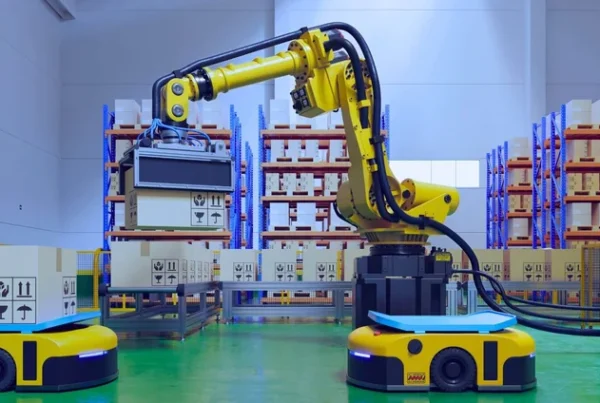

Started with warehousing, IQ Robotics is now an emerging warehouse automation leader in the Middle East. Designed for the ever-changing requirements of businesses in the region, same-day delivery and high efficiency processing is non-negotiable. IQ Robotics combines robotic picking systems with intelligent software that assist warehouses in increasing throughput and decreasing operational costs. The systems are built to scale from high volume partners down to medium warehouses with fast growing inventory.

Practices for warehouse picking automation

To fully utilize warehouse automation UAE, you have to do it following some guidelines. The first thing that you should do is take a look at your warehouse layout, as well as how your inventory flows from one area to the next. Automation is a double-edged sword — it is at its most efficient when there are clear tracks for the robots to follow and storage area has been organized with that in mind. The second point of choice concerns the selection of the most appropriate picking technology. A robotic arm may help in certain applications and a shuttle system or mobile robots are required for others.

Data Integration

With IQ Robotics all of the picking systems are firmly implanted in the warehouse management software. Leading to be able to keep track of the inventory in real-time, fewer stockouts and better order accuracy. Last but definitely not least, continuously training the staff is intended to fill in a kind of interstitial that should exist between human oversight and machine efficiency so operations can run smoothly.

Dubai Surface Properties in Action

The solution had been success case study in Dubai for several large warehouses. For instance: A leading e-commerce retailer reduced its order picking time by more than 60% after adopting automated systems. An additional logistics company experienced a significant reduction in the frequency of human errors and was able to increase its daily order volume without having to increase staff. This shows that it is a sustainable system and reasonable solutions prove warehouse automation as not just a trend, but an aged-old answer to many real-life situations. This is key to have implemented as it gives businesses a competitive advantage in today’s fast-moving tech-based market now.

The Future of Smart Warehousing In UAE

Dubai is setting itself up to be a smart logistics hub, so widespread adoption of warehouse automation UAE should come as no surprise. Dubai 10X and national AI strategies are providing an embryonic environment for companies such as IQ Robotics to expand their operations and evolve. The region will only become stronger and better to be the next Centre of Supply Chain Excellence when Automation picking is picked up by more businesses.

Conclusion

Dubai Changing the Game with Automated Warehouse Picking. In Dubai, picking tasks are being automated for goods to move from shelf to shipment. IQ Robotics is changing game by delivering scalable, smart, and highly efficient-making a move from people-led to robot done. With public use cases and a clear regulatory framework laid out businesses in the UAE have more opportunities than ever to achieve new levels of efficiency and growth. The way of the world today is simply too quick for anyone to get bogged down by slow, manual picking.

FAQs

What is warehouse picking automation?

Warehouse Picking Automation: The process of locating, selecting and retrieving items in a warehouse for the purposes of order fulfillment can be handled through Convolutional Neural Networks (Image Processing Systems) and Robotics built to perform these operations.

How IQ Robotics is Supporting Automation of Dubai Businesses?

IQ Robotics is a flexible, innovative and intelligent robotics solution for transport in one of the most rapid logistics industries in Dubai. This spans robotic arms, autonomous mobile robots (AMRs), and AI-driven software to optimize the warehouse picking process to lift throughput not by percent points but 10x coupled with less errors.

So, what advantages do automated picking systems offer?

Automated picking is done: -at lower cost per hour of order picking labor than manual picking, -with less human error rate, and at a higher order line throughput rate than manual picking, thereby enabling operation 24/7.

How SME Warehouses Can Leverage IQ Robotics Solutions?

IQ Robotics: Yes, for large and mid-sized operations (scalable systems). The benefits of robotic systems in this sector are twofold: traditional automation methods (industrial robots) tend to be too static for the ever-changing warehouse environment.

Are picking systems automated future-proof?

Absolutely. With the massive growth in e-commerce and customers demanding higher levels of service, automated picking systems can provide this possible long-term return on investment. Thanks to regular software updates, plugin-free scalability and the booming tech innovation support in Dubai, these solutions are built to last a long time.

Stay Connected

Want to see more insights on warehouse automation and smart logistics? Join the conversation and stay updated with the latest in robotic sortation systems by following us on Facebook. We regularly share innovations, case studies, and behind-the-scenes looks into how automation is reshaping fulfillment. Follow us on Facebook and be part of the future of warehousing.