Introduction

UAE Warehouses Taking Shape: New look, changing structure for warehouses in the UAE. An increasing number of shops are employing robots to take care of everyday tasks. This change isn’t simply a technical one, it’s about tapping into reality’s deep pocket of technology problems, speed, accuracy, and cost. As e-commerce swells and delivery times contract, companies seek out smarter ways to move stuff, which is where warehouse robotics comes in.

What, Exactly, Are Warehouse Robots Doing?

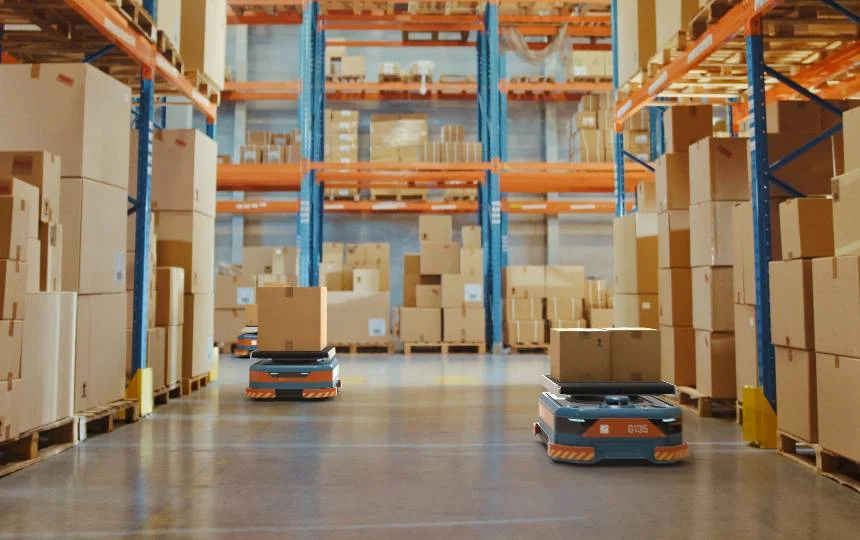

Warehouse Robotics is used to move, sort, pick, and place items. Instead of workers marching back and forth all day, robots ferry goods around. Some even scan and organize on their own. This helps move the work along more quickly and without exhausting anyone. In busy areas such as logistics hubs in Dubai, robots are maintaining the flow of work with no slowdown in sight. They also cut down on errors, resulting in fewer returns or lost parcels.

Why UAE Businesses Are Making the Transition

The UAE has never been slow to experiment with new ideas. Warehouses are staying ahead of the game with robotic technology. Labour costs, space constraints, and soaring demand are all significant. Robots don’t require breaks, and they are effective in tight quarters. They are also there during busy shopping times when human assistance might be lacking. For businesses that manage large daily volumes, the ability to automate processes is not just helpful, it’s quickly becoming a must-have.

It’s Not Just About Speed

The speed is important, but so is the accuracy. Robotscan can also scan objects, take stock , and follow precise paths. They don’t get their labels mixed up or inadvertently skip steps. This is what contributes to making the supply chain more trustworthy. Key in industries such as food, fashion, or electronics is to keep items safe and well organized. Today, many firms in the U.A.E. are using robots to monitor inventory more effectively and prevent waste or loss, for example.

Training and Humans Do Matter

But with all the automation, people are still a big part of the story. Workers control the robots now and make fixes when they are necessary. They will also handle things that require judgment or care. Warehouse robotics is a way to make jobs easier by taking away heavy lifting and long hours. Robots do not replace people; they assist them. The U.A.E. is also investing in training so that more workers can be trained on how to work with machines.

Smart Systems in Logistics

Robots are only half the story. They operate in conjunction with software that maps and directs the entire warehouse. These intelligent systems keep track of orders, plan routes, and figure out the optimal way to keep items in storage. Everything is linked and in real time, so managers know at every moment what is going on. Clear data means decisions are made faster and smarter. That makes the whole supply chain more resilient, from suppliers to consumers.

Looking Ahead: What’s Next?

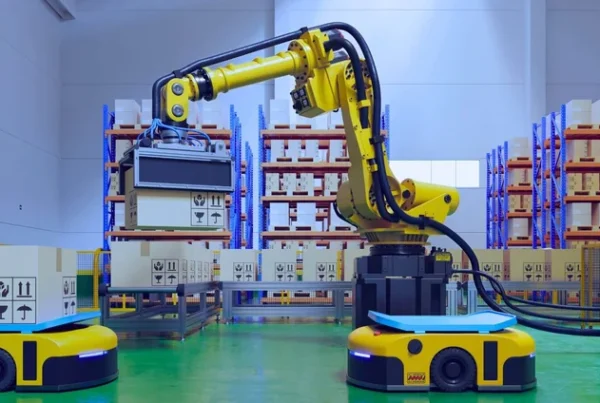

Warehouse robotics in the UAE is still on the rise. Some businesses are experimenting in other ways with robots. From drones that fly through warehouses to robotic arms that pack boxes, the new wave of warehouse automation in the UAE is not simply a way to cut workers but a way to increase efficiency and remove humans from the process. Even modest companies can profit as the technology becomes cheaper. It’s not about turning warehouses into machines, but about making them faster, safer, and more effective for all who work there.

Robots Save Space in Crowded Warehouses

Many UAE warehouses are cramped for space. Resources are scarce and demand is high, so it can become crowded in a hurry. Robots assist by better using space. They can navigate tight spaces and give access to high shelves. That means companies can store more volume while not having to expand buildings. Some robots are better at stacking goods than people. That’s a major boost to businesses trying to navigate narrow city streets.

A Safer Environment for Everybody on the Floor’

Warehouse work is dangerous. Heavy lifting, long hours, fast-moving carts: All of it can lead to accidents. Robots help shield against these risks by taking on the hard, tiring labour. Machines doing the lifting means human workers are safer: They also prevent climbing safety accidents and falls. Robots are now commonly utilised in many UAE warehouses to enhance safety. This results in fewer injuries and a better operation.

Seasonal Rush More Manageable

Warehouses can become quite busy during holidays or sales. Orders come in, and workers hustle to keep up. Robots can work on this added load without becoming fatigued. They work around the clock, and with them, we can process more orders in less time. This results in less waiting for customers. UAE businesses, which employ the use of robots at peak times, can maintain a schedule easily. That keeps customers satisfied and gives companies room to grow.

Customisable Robots Depending on Your Needs

Robots are not interchangeable. Some are designed to carry boxes. Others pitch in by packing or scanning goods. Brands in the UAE currently use all manner of robots as per their requirements. This helps to better approach work in an orderly manner. A clothing warehouse, for instance, might use smaller, quicker robots. A furniture warehouse may require something more robust. Performance is so much better if you get the right kind.

Local Support Is Growing Fast

And like robots in warehouses, as more companies in the U.A.E. employ robotic warehouse technology, so too are support systems. Local tech companies now provide repair, setup, and training. That makes it easier for companies to get started with robots. They do not have to rely on outside aid or suffer long wait times. And with local support, companies can fix problems faster and train staff better.” It’s making even more warehouses feel comfortable going automated.

Good for Fast-Growth Businesses

Stock management gets more complicated as small businesses expand. And more orders come in, and there’s no room for mistakes now. Robots help get this under control. They process goods more quickly and track stock better, which lets owners concentrate on higher aspirations. A lot of new companies in the U.A.E. are starting with robots at the outset. That way, they can grow without becoming overwhelmed.

Reduced Stress on Warehouse Teams

The work in the warehouse can be exhausting. Picking, lifting, and sorting all day wears on you. Robots do the heavy lifting. That allows people to spend more time on smarter tasks. It also takes the pressure off when you have a busy day. Between exchanges, employees are less fatigued and more likely to avoid making a mistake. Ultimately, the entire team does better.

Robots Don’t Take Days Off

Robots never stop, never sleep. They don’t require breaks, vacation, or sick leave. That can make a big difference at peak times. And also, entertaining the masses — well, all of New York who happen to be up for it — until whenever they can keep things going after hours. There are now UAE warehouses that operate 24 hours a day, seven days a week, thanks to robots. This allows them to meet extremely tight deadlines and demands.

Saves Money Over Time

Robots can come across as expensive, initially. But in the long run, they save money. Fewer errors, faster working, and better storage capabilities sit on the other side of the ledger. Organisations also save on the cost of rectifying human errors. For most companies, it takes a few years to pay it off. It’s why more UAE companies are going for automation.”

The U.A.E. Is Prepared for This Shift

Smart cities and robust links to transport are being built in the UAE. That’s why it makes a great home for warehouse robots. The government is behind tech in business. Companies are more willing to experiment with new systems. With demand up and space tight, the moment is opportune. And warehouse robots are just the ticket for the country’s large ambitions.

Keeping Track Becomes Easier

Robots not only transport items — they also gather data. They scan barcode labels and update stock counts in real time. This enables managers to know precisely what is in the warehouse. Dials don’t need to be manually counted or guessed at. It’s easier to figure out what went wrong if something goes missing. In the U.A.E., where speedy shipping is key, such tracking can prevent delays.

Helps Cut Down on Waste

Errors in storage and packing frequently result in waste. It costs money when things are broken, when the wrong items ship, or when stock is mismanaged. Robots solve these problems by sticking to predetermined routes and procedures. They don’t miss steps or forget instructions. That’s less trash and fewer returns. Robots are making the AE’s warehouses cleaner and more efficient.

A Step Toward the Future

The move to warehouse robotics is not just a tech trend. It’s a true transformation in how business is done. Robotics Companies in Dubai that have adopted robots are gearing up for the next step. They’re creating better systems that can accommodate more. This transition won’t be overnight. Warehouses across the country, however, are getting smarter and faster step by step, with robots taking the lead.

Conclusion: Warehousing robotics broken down for the future of the UAE

In other words, when we say warehouse robotics explained, it just means less delay, fewer errors, and smoother operations. For UAE companies, the goal is to stay prepared for the future. Robots bring calm to hectic warehouses, helping people do their jobs better. And as the appetite for rapid delivery grows, automation will underpin how things move behind the scenes. No, it’s not a craze - it’s the new normal.

Let’s Connect with IQ Robotics

If you’re exploring how automation and robotics can transform your warehouse operations – or just curious about where the future of logistics in the UAE is heading – I’d love to connect. I regularly share insights on smart technologies, supply chain trends, and the evolving role of AI in logistics. Feel free to reach out or follow me on LinkedIn to keep the conversation going.