Warehouse Robotics

Automation and smart technologies are quickly turning the UAE into a global logistics hub. Warehouse robotics is one of the largest game-changing innovations that has heavily influenced this industry. As the boundaries expand for e-commerce, manufacturing, and supply chain operations, businesses have started adopting robotics to make things more efficient, cut costs, and increase monthly productivity.

What is Warehouse Robotics?

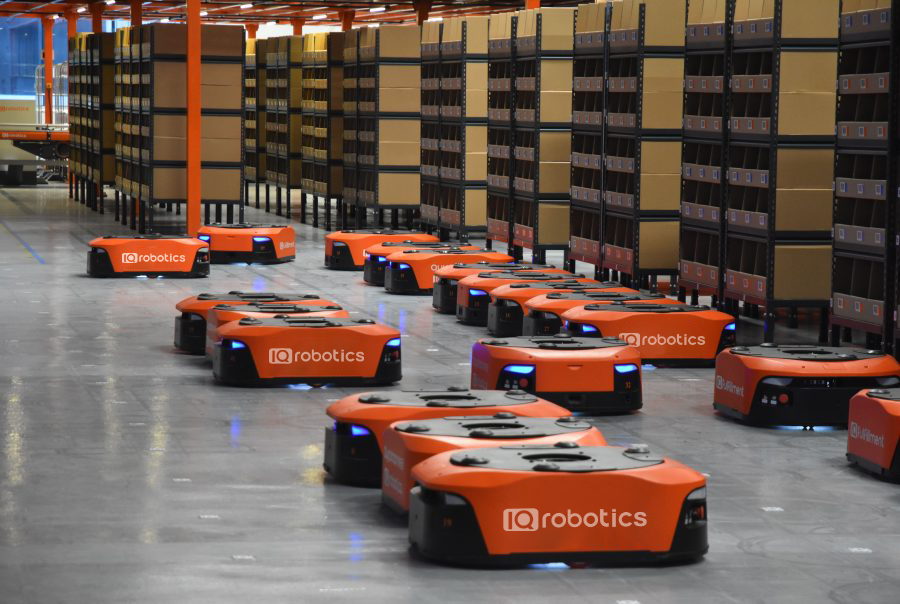

Warehouse robotics denote the employment of automatic systems, namely automated guided vehicles (AGVs), autonomous mobile robots (AMR), robotic arms, and artificial intelligence-aided sorting systems, to enhance warehouse operations and create lean systems. These systems help carry out tasks such as picking, packing, sorting, inventory management, and transportation, eliminate human labor, and improve accuracy. (See More)

Why is warehouse robotics growing in popularity in the UAE?

Yet, the pace of growth of the UAE’s logistics and e-commerce industries has been unprecedented. As consumer demand for faster deliveries and better supply chain management continues to rise, so does the number of businesses turning to warehouse robotics to remain competitive. This is why robotics is turning out to be the key to advancement in the warehouse industry in UAE:

1. Increased Efficiency and Productivity

Warehouses that run on staff can no longer process orders as fast without putting people in overtime and making people fatigued. Robotic picking and sorting systems help businesses fulfill orders in minutes, not hours, reduce delivery times, and increase customer satisfaction.

2. Reduced Operational Costs

The initial cost of warehouse robotics is high, but the long-term cost can be significantly reduced through labor cost reduction, error minimization, and better storage utilization. Robots enable businesses to shift human workers to more strategic tasks while robots take over repetitive ones.

3. Improved Accuracy and Order Fulfillment

Order picking and inventory management errors can be costly and cause unhappy customers. Warehouse robots use AI-powered vision systems and machine learning algorithms for picking, packing, and inventory tracking with pinpoint precision, making the risk of being placed or shipped with errors very low.

4. Enhanced Safety in Warehouses

Usually, traditional warehouse environments are hazardous places where workers can easily get involved in accidents, heavy lifting, or suffer from repetitive strain. In the workplace, robotics improves workplace safety by taking care of dangerous work and eliminating the need for human intervention in high-risk areas.

5. Scalability for Growing Businesses

Given that the Best Robotics companies in the UAE are growing, businesses need scalable solutions to deal with the growing number of orders. The flexibility and scalability aspect of warehouse robotics allows companies to expand the robotic system as the demand rises without investing heavily in infrastructure changes.

6. Integration with Smart Technologies

Warehouse robotics fits seamlessly into its AI, IoT, cloud computing, and big data analytics ecosystem, which intelligently shares work with a robot and a human worker. It allows real-time tracking of inventory, predictive analytics, and the optimal stock chain.

7. Sustainability and Energy Efficiency

Modern robotic systems are built to ensure energy efficiency and reduce the warehouse’s carbon footprint. Robotics also leads to a more sustainable and eco-friendly supply chain by occupying less storage space, reducing waste, and contributing to better transportation logistics.

The Future of Smart Warehousing in the UAE

The UAE government is very supportive of digital transformation initiatives such as the adoption of automation and AI in logistics and supply chain management. As customers continue to demand same-day and next-day delivery, warehouse robotics will become essential in helping accomplish faster and more reliable fulfillment.

AI-Powered Predictive Analytics – Forecasting demand and optimizing inventory management using machine learning.

This includes Collaborative Robots (Cobots), such as those that are used alongside human workers to transform a factory floor into a more efficient operating environment.

Faster communication between warehouse systems—5G is central here as the spectrum of the new radio frequencies enables the faster communication required for warehouse automation.

Conclusion

The future of smart Warehouse Automation in UAE is revolutionized through warehouse robotics. Robotics is taking the traditional warehouse, making it more efficient, lowering costs, and increasing safety to transform it into 21st-century, automated ‘high-tech’ fulfillment centers. The UAE’s logistics and e-commerce sectors will be driven by success thanks to the necessary digitalization and the integration of robotics.

Companies that want to remain on the cutting edge in an increasingly competitive market, must invest in warehouse robotics if they want to sustain and grow in the long term.

As the UAE continues to lead the charge in smart warehousing and automation, staying informed about the latest trends in warehouse robotics is key to remaining competitive. If you’re looking to learn more about how warehouse robotics can benefit your business or want to discuss the future of smart logistics, feel free to connect with me on LinkedIn. Let’s explore the possibilities together!