At first, warehousing automation innovations focused on supply chain transformation were applied in industrialized nations, but are currently being extended to developing countries. Initially, warehouses were used as symbols of supply chain change, but they are now being implemented in developing countries.

The warehousing in the UAE and GCC region generally is taking off. The introduction of automation is altering the manner in which the flow of goods from ports to consumers occurs. The modern logistics activity is more based on new products and developed solutions to address the increasing demand.

Dismantling of Traditional Obstacles.

Logistic companies are faced with labour shortages, space and pressure in meeting orders. Jebel Ali Free Zone (JAFZA) and Dubai South are the hubs of high shipment of e-commerce and international trade in UAE. Using AI, intelligent vehicle navigation, and flexible warehouse technology, businesses will increase throughput, increase precision, and enhance cost management.

Changing the Warehouse Convention in the GCC.

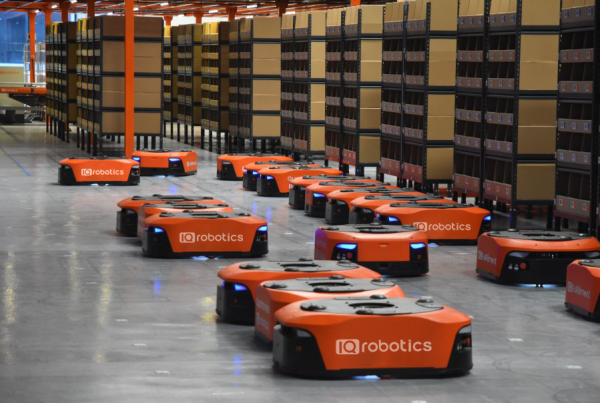

Due to the increase in trade along the Gulf, logistics providers are transforming warehouses into supply-chain performance nodes. With a company embracing the ideas of Warehouse Management System (WMS) and other robotics warehousing automation tools to supplement them, there is a possibility of serving more customers, avoiding buffer stock, and seasonal peaks. As an illustration, the UAE firms are already relying on these systems to provide efficiency at scale.

Overview

Warehousing automation of the warehouse does not mean the elimination of manual labour. It makes storage, picking, packing and dispatch simpler integrated flows. This change in the UAE is in favor of national logistics and trade objectives. The systems are now providing increased speed and utilize the data to coordinate the operation.

Key Offerings

- Provides sensors, superior software and integrated systems that provide real-time inventory visibility in GCC.

- Other applications include the provision of automated picking and storage systems that minimize space and maximize the picking density.

- Provides intelligent conveyors, robotization integration and modular shelves to scale in a short period in case of abrupt demand.

- Makes sure that the orders move through their up-take and delivery stages without a lot of human-to-human hand-offs and reduced mistakes.

- Provides productivity and cost savings throughout the warehousing business in the GCC.

Why It Stands Out

Through warehousing automation, warehouses become agile and slim. This provides a decisive operational advantage in a market such as the UAE where both the level of trade and the level of customer demands are on the rise.

Ground of supply chain resilience on logistics automation

Supply-chain resilience is grounded on logistics automation. Warehouses with sophisticated warehouse automation systems also keep the flow and consistency when world disruptions such as shipping hold-ups or labor shortages associated with pandemic-related restrictions occur. This strength is turning out to be a strategic asset in the Gulf.

Key Offerings

Implements predictive analytics to foresee the demand and optimize the stocks in advance. The flat management structure will enhance the company’s ability to generate innovation, as all three management tiers are equipped with innovative ideas and fresh ideas.

- This management structure will also improve the capability of the company to create innovation because all three management levels are armed with innovative ideas and new ideas.

- Supplies automated goods-movement (robots, conveyors) in keeping up with labor-intensive periods.

- Employs IoT-based equipment and surrounding (temperature, humidity, etc.) surveillance of goods in warehouses in the UAE with critical items.

- Enables store deliveries, e-commerce, and returns fulfilment via a unified warehouse platform.

- Allows regional operators to scale dynamically across GCC markets without full-scale rebuilds.

Why It Stands Out

It is that skill to adjust rapidly and keep upper service standards that make automated warehouses stand out in a region that requires a combination of speed and size.

Reshaping the Workforce Through Automation in GCC Logistics

Another transformation that automation brings to logistics is to the workforce, the work and/or skills. In UAE and the GCC, firms are educating teams, which are to operate smart systems, and not undertake routine tasks. This change will guarantee that human resources are aligned to strategic ability as opposed to standard functions.

Key Offerings

- Education of the staff to use Warehouse Execution Systems (WES) instead of using manual handling of orders.

- Enhances human-machine collaboration, providing the operators with the possibility to concentrate on exception-handling and value-added tasks.

- Eliminates reliance on seasonal sources of large labour forces through the implementation of flexible automated workflow.

- Enhances multi-functional visibility and traceability as the operations are better managed through improved decision-making and service delivery.

- Enhances safety and compliance through automated dangerous or repetitive activities at warehouse premises.

Why It Stands Out

The idea of upskilling the workforce and taking advantage of the use of automation is in line with regional labour-transformation objectives and guarantees the sustainability of operations.

Conclusion

The warehousing automation is transforming the operations of the supply chains in the UAE and in the GCC as a whole. Businesses are more efficient, responsive and resilient with smart systems, built-in data, and flexible operations. Warehousing automation is not a dream idea, but the basis of logistics leadership and development in the region.

Sign up at IQ Robotics to get a customized consultation or visit us on LinkedIn to get to know more.

Frequently Asked Questions

What kinds of warehouses are the most beneficiaries of the automation solutions in the GCC?

Warehousing automation is most useful in the Gulf region when it comes to warehouses where high volume picking is needed, multi-channel fulfilment, and seasonal bursts.

How fast will a logistics operator in the UAE achieve the results of using automated systems?

Measurable results in accuracy, speed or cost control can usually be realized within 3-12 months of deployment depending on scale and integration by operators.

Is automation cost-effective to the small/ medium logistics firms in GCC?

Yes — smaller operators can consider automation, using modular and cloud-based solutions with less initial investment and pay-as-you-go pricing.

What is the role of automation in terms of sustainability and efficient utilization of resources in supply chains?

Automation will eliminate wastage, space utilization, energy use and better labour performance – making logistics sustainable.

What is the reason why IQrobotics is a leader in providing warehouse automation services in the UAE and the Gulf region?

Our company is a blend of comprehensive local knowledge in logistics in the UAE, regional experience through GCC supply-chains, and collaboration with best automation technology solutions to provide region-specific solutions.